Sealless Pumps for a Safer and Greener World

When it comes to selecting the right equipment for fluid transfer or storage applications, choosing the best canned pump is crucial for ensuring efficiency and reliability. Canned pumps, known for their hermetic design and exceptional safety features, have become a popular choice across various industries, ranging from chemical processing to HVAC systems. They offer the advantage of eliminating the risk of leaks, making them ideal for handling hazardous liquids or processes that require strict adherence to safety standards.

In this guide, we will walk you through the essential factors to consider when evaluating different canned pump options. From flow rate and pressure requirements to compatibility with specific fluids, understanding your unique needs is vital. Additionally, we will address the various types of canned pumps available on the market, along with their key specifications and operating principles. By the end of this guide, you will be equipped with the knowledge necessary to make an informed decision and select the best canned pump tailored to your specific applications.

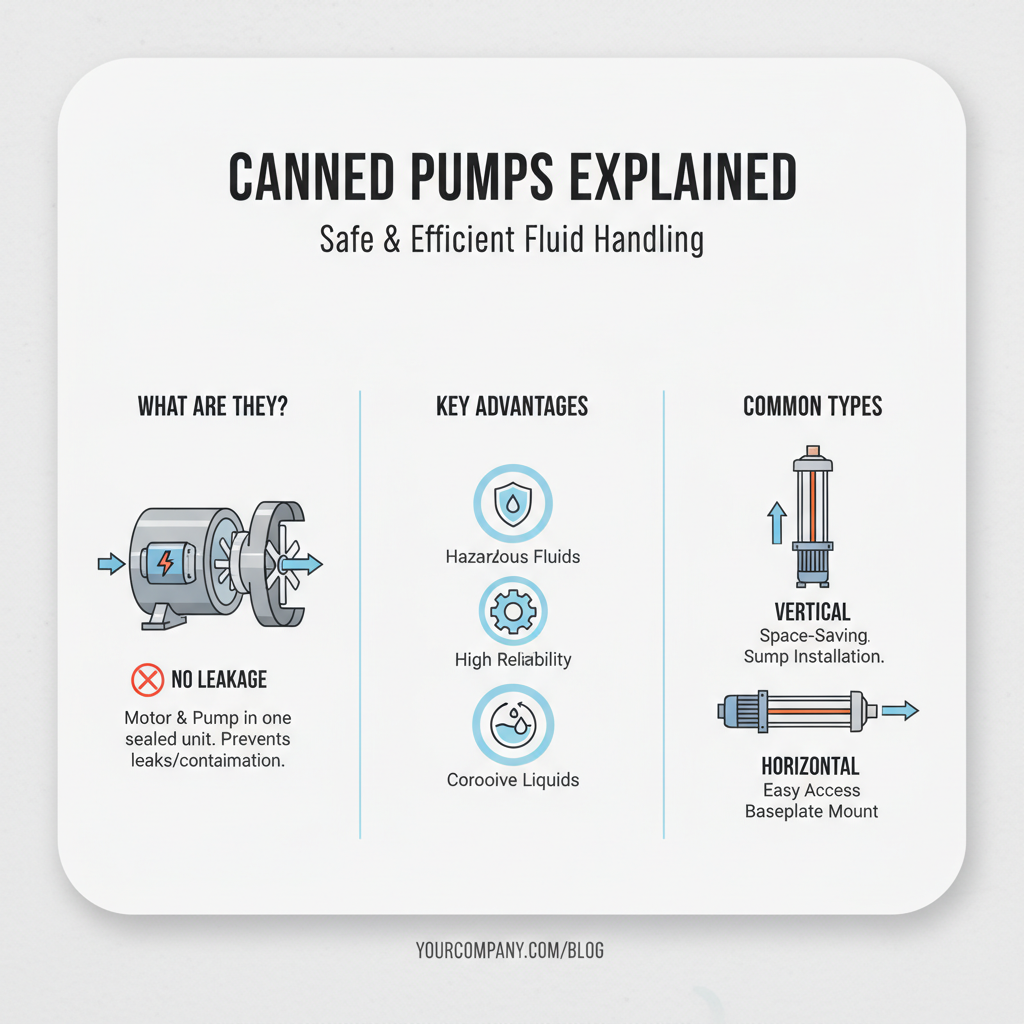

Canned pumps are specialized devices designed for the safe and efficient handling of various fluids. They are enclosed systems where the motor and pump are housed in a single unit, separated from the fluid being pumped. This design is particularly advantageous for handling hazardous or corrosive liquids, ensuring that there is no leakage or contamination. Understanding the different types of canned pumps is essential for selecting the right one for your application. Common types include vertical and horizontal configurations, each suited for different installation environments and operational needs.

The applications of canned pumps are diverse and span across multiple industries. In chemical processing, they are used for transporting acids and alkalis, where traditional pumps may risk corrosion or environmental hazards. In the pharmaceutical industry, these pumps ensure the integrity and purity of sensitive liquids. Additionally, they are employed in food and beverage applications, where hygiene and safety are paramount. By identifying the specific requirements of your operation—such as flow rate, fluid characteristics, and environmental conditions—you can choose a canned pump that not only meets safety standards but also enhances operational efficiency.

When selecting a canned pump, it's crucial to evaluate several key factors that directly impact performance and suitability for your application. Firstly, consider the specific fluid being pumped. The viscosity, temperature, and chemical compatibility of the fluid will dictate the materials used in the pump’s construction and affect its overall efficiency. For instance, aggressive chemicals may require pumps made of corrosion-resistant materials, while higher viscosities may necessitate pumps with different impeller designs to maintain effective flow rates.

Secondly, assess the required flow rate and pressure for your system. Canned pumps are available in various designs optimized for different flow capacities and head pressures. It’s essential to choose a model that meets or exceeds your application’s demands to ensure reliable operation. Additionally, consider the pump’s energy efficiency and maintenance requirements. An energy-efficient design can lead to significant cost savings over time, while ease of maintenance will reduce downtime and operational disruptions. By carefully evaluating these factors, you can select the best canned pump that fulfills your operational needs.

| Pump Type | Flow Rate (GPM) | Max Pressure (PSI) | Material | Motor Type | Price Range |

|---|---|---|---|---|---|

| Diaphragm Pump | 1.5 | 60 | Polypropylene | Electric | $200 - $300 |

| Centrifugal Pump | 3.0 | 80 | Stainless Steel | Electric | $150 - $250 |

| Peristaltic Pump | 0.8 | 50 | Silicone | Electric | $100 - $200 |

| Gear Pump | 2.0 | 100 | Aluminum | Electric | $250 - $350 |

| Vane Pump | 1.2 | 70 | Cast Iron | Electric | $180 - $280 |

When selecting the best canned pump for your applications, understanding the performance and reliability of various brands is crucial. According to a recent market analysis by Frost & Sullivan, the global canned pump market is expected to grow significantly, maintaining a composite annual growth rate (CAGR) of 7.2% from 2023 to 2028. This growth highlights the increasing demand for reliable pumping solutions in industries such as chemical processing and food production, where consistency and safety are paramount.

Comparing leading brands, it's essential to consider metrics such as flow rate, operational efficiency, and durability. A report by Research and Markets indicates that top performers in the canned pump sector, like Xylem and Grundfos, consistently exceed performance benchmarks with efficiency ratings over 85%. Their advanced engineering designs result in longer lifespans and reduced maintenance needs, further enhancing their reliability.

When choosing a canned pump, assessing these performance metrics not only ensures optimal operation but also minimizes downtime and operational costs in the long run.

When it comes to maintaining the longevity of a canned pump, regular care and attention are essential. One of the most crucial tips is to ensure that the pump is properly lubricated. Check the manufacturer’s guidelines for the recommended lubricants and intervals. Keeping the internal parts well lubricated reduces friction and wear, leading to smoother operation and a longer lifespan.

Another important maintenance practice is to inspect the filter regularly. Clogged filters can hinder the efficiency of a canned pump and may even cause overheating. Clean or replace the filters as needed, and consider implementing a schedule for routine checks. This proactive approach will help prevent minor issues from escalating into major repairs.

Lastly, ensure that the operating environment is optimal. Canned pumps are often sensitive to temperature and humidity variations. Protecting the pump from extreme conditions not only enhances its performance but also extends its years of service. By following these maintenance tips, you can maximize the lifespan of your canned pump and ensure it operates at peak efficiency.

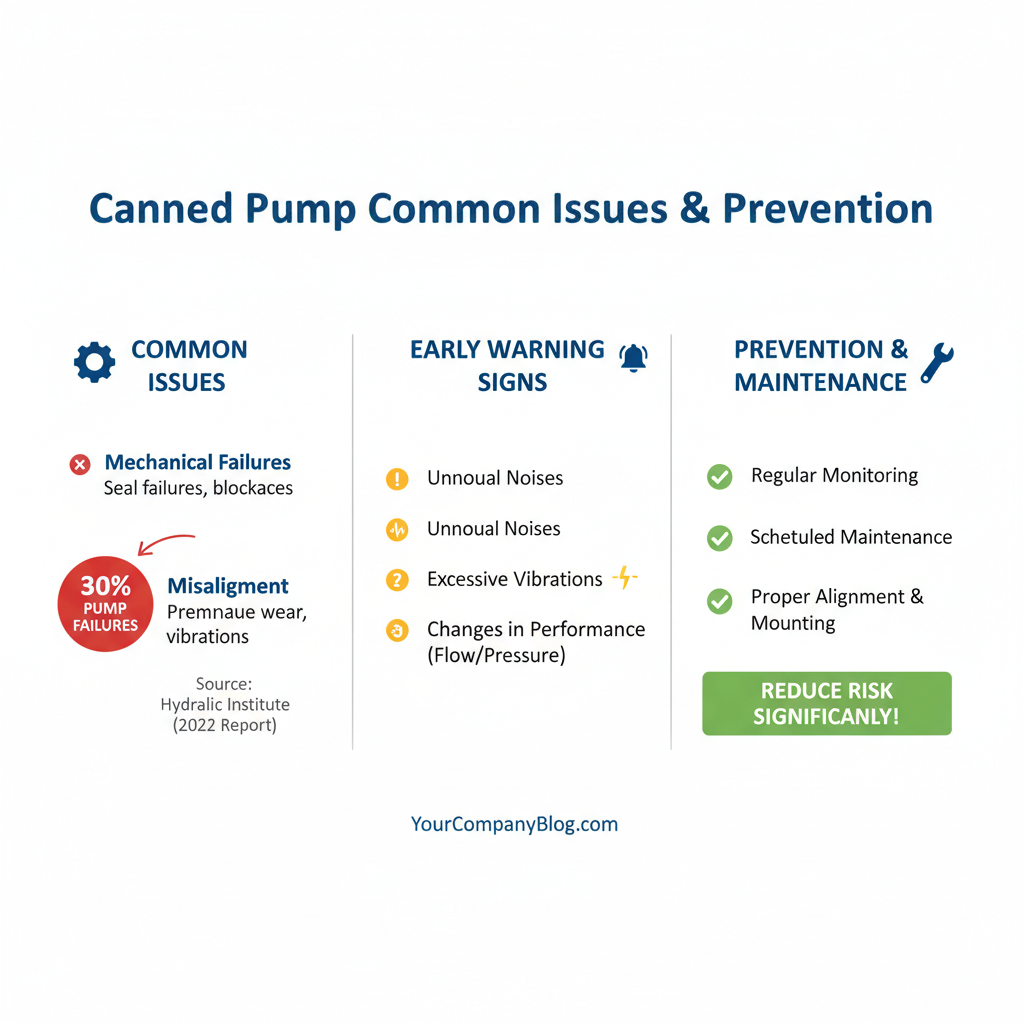

When it comes to canned pumps, users may encounter a range of common issues that can disrupt operations. According to a 2022 report by the Hydraulic Institute, nearly 30% of pump failures are attributed to mechanical issues such as seal failures or blockages. Regular maintenance and monitoring can significantly reduce the risk of these problems. Users should routinely check for unusual noises, vibrations, or changes in performance that may indicate underlying issues. Additionally, ensuring proper alignment and mounting is crucial, as misalignment can lead to premature wear.

Another notable concern is cavitation, which occurs when the pressure in the pump drops below vapor pressure, causing vapor bubbles to form and collapse. Data from the Pump Systems Matter initiative indicates that approximately 24% of pump operational issues stem from cavitation effects, often resulting in substantial downtime and repair costs. To mitigate cavitation, it’s important to maintain adequate inlet pressure and ensure the pump is sized correctly for the application. Regularly consulting a qualified technician to review operating conditions can help pinpoint potential problems before they escalate into major failures.