Sealless Pumps for a Safer and Greener World

Chemical pumps play a critical role in various industries. They transport corrosive and hazardous liquids with precision. Choosing the right pump can enhance safety and efficiency. However, the selection process can be daunting and complex.

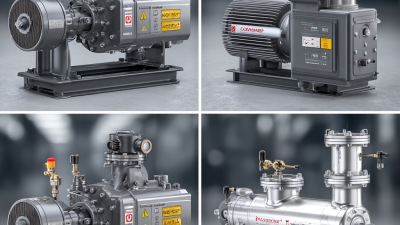

In this article, we will explore the top 10 chemical pumps you need to know about. Each pump has unique features tailored to different applications. Some may excel in handling high-viscosity fluids, while others are better suited for aggressive chemicals. It's essential to understand these distinctions to make informed choices.

As you delve into the world of chemical pumps, think about the potential challenges. Not all pumps perform well under stressful conditions. Some may require frequent maintenance, leading to unexpected downtime. This article will guide you through both reliable options and those that may need a closer inspection.

Chemical pumps are crucial in various industrial applications, ensuring the safe and efficient transport of liquids. There are several types of chemical pumps that cater to different needs and processes. Here are some key types to consider.

Centrifugal pumps are commonly used. They operate by converting rotational energy into fluid energy. This design is great for low-viscosity liquids but may struggle with slurries. In contrast, diaphragm pumps are robust. They can handle viscous and abrasive fluids, making them ideal in tougher environments.

Tip: Always assess the fluid type before choosing a pump. A mismatch can lead to reduced efficiency or even equipment failure.

Peristaltic pumps operate through flexible tubing. They are suitable for sanitary applications, like food and pharmaceuticals. However, they may not be the best option for high-pressure scenarios. Another type, gear pumps, delivers a precise flow rate. They work well with viscous liquids but could cause issues with shear-sensitive fluids.

Tip: Consider the maintenance requirements of your chosen pump. Some designs require more frequent attention than others.

In conclusion, knowing the different types of chemical pumps can significantly impact your operations. Each type serves a unique purpose. It’s essential to reflect on your specific needs to make the best choice.

| Pump Type | Key Features | Common Applications | Flow Rate (L/min) | Max Pressure (bar) |

|---|---|---|---|---|

| Centrifugal Pump | High capacity, simple design | Water, acids, and chemicals | 3000 | 10 |

| Diaphragm Pump | Self-priming, excellent for viscous fluids | Pesticides, soaps, and coatings | 200 | 6 |

| Gear Pump | High-pressure capability, suitable for viscous materials | Oil, paint, and food products | 500 | 15 |

| Peristaltic Pump | Minimal contamination risk, easy maintenance | Food and beverage, pharmaceuticals | 150 | 2 |

| Magnetic Drive Pump | Leak-proof, suitable for hazardous fluids | Chemicals, solvents | 1000 | 8 |

| Progressing Cavity Pump | Handles slurries and viscous fluids | Wastewater, food waste | 600 | 12 |

| Screw Pump | High efficiency, low pulsation flow | Hydraulic fluids, lubricants | 400 | 20 |

| Rotary Lobe Pump | Gentle pumping action, can handle solids | Food processing, pharmaceutical | 350 | 8 |

| Vane Pump | Compact design, smooth flow | Hydraulic fluids, light oils | 250 | 5 |

| Bladder Pump | Handles viscous and abrasive fluids | Sludge, slurry | 500 | 10 |

When choosing a chemical pump, understanding key features is crucial. Each type serves distinct needs, impacting efficiency and safety. Centrifugal pumps, for example, are widely used for their efficiency in transporting low-viscosity liquids. They operate best within specific flow rates. However, they can struggle with high-viscosity fluids, leading to performance issues.

Diaphragm pumps offer a different advantage. These pumps handle corrosive and abrasive liquids effectively. They provide a leak-free operation, which is essential in sensitive environments. However, they might have lower flow rates than centrifugal pumps. A study shows that diaphragm pumps can maintain a consistent flow even under varying pressure conditions, which is a plus.

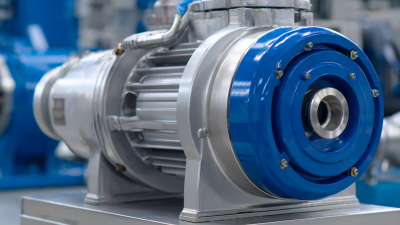

Magnetic drive pumps are gaining traction due to their sealless design. They minimize the risk of leaks. This feature is vital, considering that leaks can lead to costly downtime. Yet, maintenance can be more complex and requires specialized knowledge. Reports suggest that users should weigh the upfront costs against long-term benefits in safety and efficiency. Understanding each pump's nuances can lead to better decision-making in chemical handling processes.

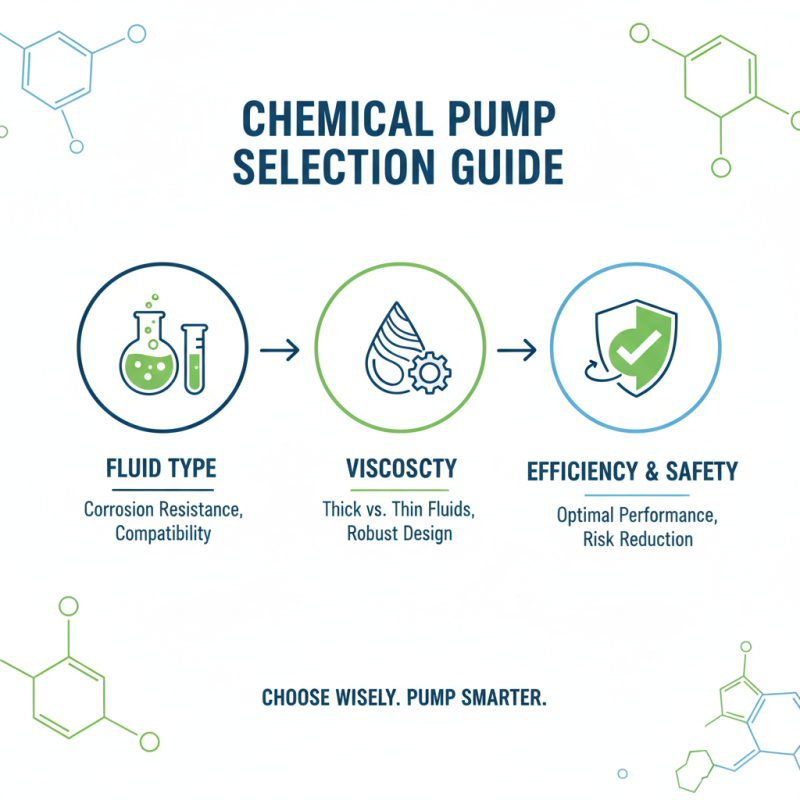

Choosing the right chemical pump is crucial for efficiency and safety. Start by considering the type of fluid you will handle. Different chemicals can require specific materials to prevent corrosion. Ensure the pump can handle the viscosity of your fluid. Thicker fluids may need a robust design.

Next, think about the flow rate needed for your operations. A pump must deliver enough capacity without overworking. It's important to measure exactly what you need. If a pump is oversized, it could lead to waste. Additionally, consider the environment. A pump should be suitable for the area it will be used.

Don't overlook maintenance requirements. Some pump designs may be easier to service than others. Regular maintenance is key to performance. Reflect on your past experiences. Have you faced unexpected breakdowns? Evaluate your choices to avoid future issues. A well-thought-out selection can save time and resources in the long run.

Chemical pumps play a crucial role in various industries, handling aggressive fluids daily. To ensure longevity, proper maintenance is essential. Regular inspections can identify issues early. Studies show that 70% of pump failures stem from inadequate maintenance. Keeping an eye on vibration levels can prevent costly breakdowns.

Another key factor is fluid compatibility. If pumps are not compatible with the chemicals they handle, wear can increase dramatically. Reports indicate that improper material selection can reduce lifespan by up to 50%. Operators should review specifications regularly to avoid such pitfalls.

Cleaning the pump and its components is also vital. Residue buildup can hinder performance and efficiency. Following manufacturer guidelines can help maintain optimal operation. Ignoring these tips may lead to inefficient pumps, resulting in increased operational costs.

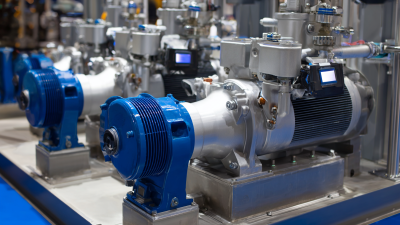

Chemical pumps are essential in various industries, playing a crucial role in fluid transfer. These pumps handle corrosive, viscous, and hazardous liquids. Common applications include chemical processing, water treatment, and pharmaceuticals. In chemical plants, pumps move acids and bases with precision. This minimizes risks and increases safety.

In water treatment facilities, chemical pumps are vital. They help inject chemicals for purification. This ensures clean drinking water is available. Without reliable pumps, treatment processes could fail, leading to health risks. The pharmaceutical industry also relies heavily on these pumps. They ensure sterile solutions are delivered accurately during drug manufacturing.

Tips: Always check the pump specifications. This helps in selecting the right one for your needs. Regular maintenance is key. Inspect seals and bearings regularly to avoid leaks. Remember, improper handling of chemical pumps can lead to spills. This can have serious environmental consequences.