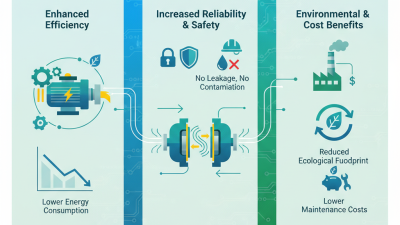

Sealless Pumps for a Safer and Greener World

When selecting pumps and motors, understanding your specific needs is vital. Various applications require different systems. Pumps and motors come in numerous types and configurations. Each option has strengths and weaknesses. This diverse landscape can be overwhelming.

Consider factors such as flow rate, pressure, and power. Different environments may demand unique specifications. Think about efficiency and maintenance needs too. The right equipment can reduce long-term costs. However, it's easy to overlook essential details. Rushing this decision can lead to costly mistakes.

Making an informed choice is crucial. Evaluate the total cost of ownership. Speak with experts to gather insights. Don't ignore feedback from previous users. Learning from their experiences can guide you. The goal is to strike a balance between performance and reliability. The right pumps and motors will meet your operational demands.

When selecting pumps and motors, understanding the types available can be quite overwhelming. Each type serves different purposes and applications. Centrifugal pumps are common in many industries. They operate by converting rotational energy into fluid motion. This design is great for transporting large volumes of fluid. However, they may struggle with thick or viscous liquids.

On the other hand, positive displacement pumps push fluid through a chamber. They are ideal for thick liquids or harsh environments. These pumps deliver a steady flow regardless of pressure changes. Yet, they can be overrun if there’s no outlet, creating potential hazards. Knowing your fluid’s viscosity and flow requirements is crucial.

Electric motors come with various specifications too. Whether you need AC or DC motors, the right choice will impact performance. AC motors are often more efficient but may require more maintenance. Meanwhile, DC motors offer precise control but can be pricier in the long run. It's important not to overlook the power ratings and speed requirements. Finding the perfect match requires careful thought and consideration.

This chart illustrates the different types of pumps and motors available in the market, along with their common applications and efficiency ratings. Understanding these options will help you make informed decisions for your specific needs.

When selecting pumps and motors, evaluating specific application needs is crucial. Understanding flow rate, pressure, and fluid type helps narrow choices. For example, the American Society of Mechanical Engineers recommends assessing your application's pressure requirements thoroughly. A slight miscalculation can lead to inefficiency or equipment failure.

Performance requirements should align with operational conditions. Do you need variable speed control or constant flow? A study by the Hydraulic Institute indicates that 20-30% of energy in pump systems is wasted due to mismatched performance. Selecting the right specifications can enhance efficiency. However, many overlook maintenance needs. Regular checks are essential for long-term performance but are often ignored.

Consider real-world applications too. Industrial settings may demand heavy-duty components. In some cases, operators underestimate the importance of durability. Factors like temperature fluctuations and corrosive substances can drastically affect lifespan. Regularly revisiting these factors can improve operational reliability and reduce unexpected costs. Balancing various components leads to a functional yet efficient setup.

When selecting pumps and motors, efficiency is crucial. A report by the U.S. Department of Energy suggests that optimizing pump efficiency can reduce energy costs by up to 20%. Many pumps operate at only 40-60% efficiency. This makes choosing the right model vital for energy savings and operational effectiveness.

Size matters too. A pump that is too large may waste energy, while one that is too small may not meet demand. Accurate sizing prevents costly downtimes. The Hydraulic Institute provides guidelines, stating that the wrong size can reduce performance by as much as 30%. It's essential to evaluate the application and measure flow rates properly.

Power ratings must align with application needs. A motor's power efficiency can determine operational lifespan. Industry data shows that motors with higher efficiency ratings (like IE3 and IE4) tend to last longer and perform better. Unfortunately, many users overlook this detail, leading to frequent replacements and unexpected costs. Consider these factors carefully to ensure effective and efficient performance.

| Type | Efficiency (%) | Size (inches) | Power Rating (HP) |

|---|---|---|---|

| Submersible Pump | 85 | 6 | 1.5 |

| Centrifugal Pump | 90 | 8 | 5 |

| Diaphragm Pump | 75 | 4 | 0.75 |

| Gear Pump | 78 | 5 | 3 |

| Peristaltic Pump | 82 | 3 | 1 |

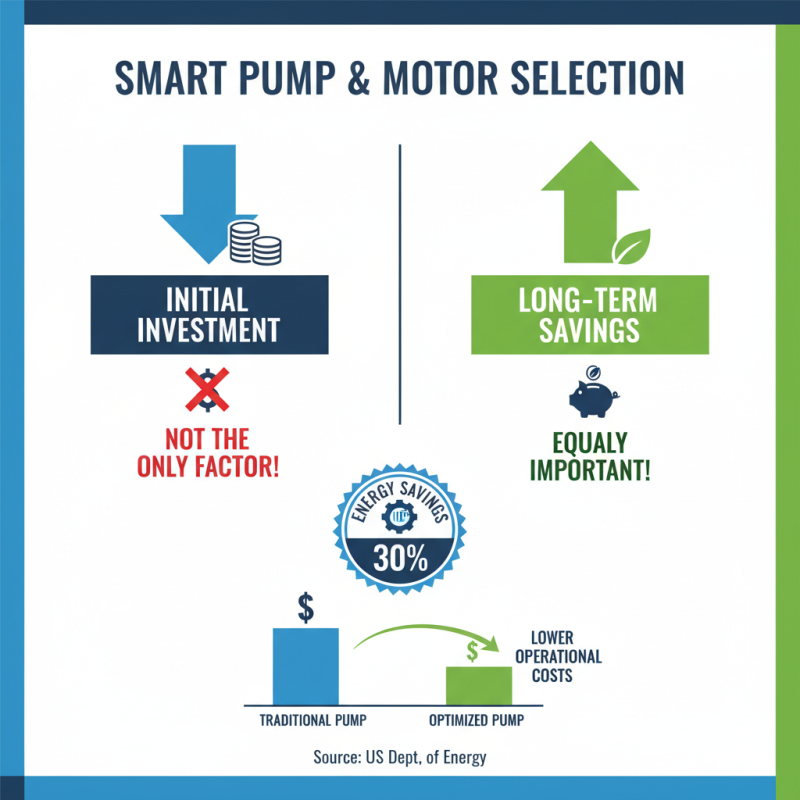

When selecting pumps and motors, assessing costs is vital. Initial investment isn't the only factor; long-term savings are equally important. A study by the Department of Energy highlights that properly selected pumps can lead to energy savings of up to 30%. This reduction can dramatically lower operational costs over time.

Consider the efficiency of these systems. Higher efficiency often correlates with higher upfront costs. However, the payback period can be surprisingly short. According to the U.S. EPA, upgrading older pumps can yield annual savings of thousands of dollars. Factors like maintenance and energy consumption should guide your choices.

Reflect on operational needs as well. Oversized pumps can waste energy. A study by the Hydraulic Institute revealed that oversized pumps operate inefficiently, costing 10-20% more than necessary. Understanding your specific requirements can help strike a balance between upfront costs and long-term operational efficiency, resulting in smarter investment decisions.

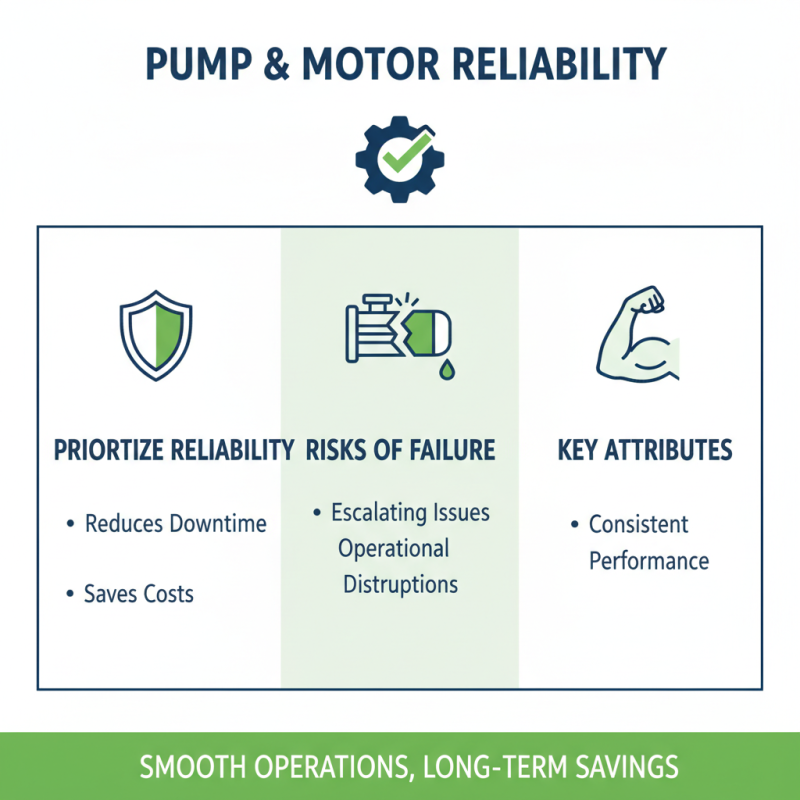

When selecting pumps and motors, reliability is paramount. A dependable pump can keep operations running smoothly. A malfunctioning unit can lead to costly downtime. Small leaks or intermittent failures can escalate quickly. Prioritizing reliable options often pays off in the long run. Each component should be evaluated for durability and performance.

Maintenance is equally critical. Regular checks can help identify potential issues early. For example, wear on seals or bearings can be detected before they cause major failures. Scheduled maintenance routines can also extend the life of both pumps and motors significantly. It is essential to have a plan that incorporates periodic inspections and necessary repairs.

Choosing the right equipment involves not just the purchase, but ongoing care. A solid strategy for reliability and maintenance can enhance efficiency. However, companies sometimes underestimate the complexity of upkeep. A simple oversight can lead to unexpected breakdowns. Reflecting on previous mistakes can guide better decision-making in the future. Investing time in understanding maintenance needs ensures that your selected pumps and motors perform optimally.