Sealless Pumps for a Safer and Greener World

In the realm of industrial applications, the quest for enhanced efficiency and reliability has led to the widespread adoption of sealless pumps. These innovative devices, which eliminate the conventional seals commonly found in standard pumps, are becoming increasingly vital in sectors where leakage and contamination can pose considerable risks. Dr. Jane Smith, a renowned expert in the field of fluid dynamics, emphasizes the transformative role of sealless pumps, stating, "The use of sealless pump technology not only reduces maintenance costs but also significantly enhances operational safety."

The benefits of sealless pumps extend beyond mere functionality; they also address critical environmental concerns. By minimizing leakage, these pumps help organizations comply with stringent environmental regulations, ultimately reducing their ecological footprint. Furthermore, the efficiency of sealless pumps translates into lower energy consumption, making them an attractive choice for businesses aiming to optimize their operational costs while contributing to sustainability efforts.

As industries continue to evolve, the integration of sealless pump technology promises to play a pivotal role in improving system performance and reliability. With the insights from experts like Dr. Smith guiding the narrative, it is evident that sealless pumps are not just a trend but a fundamental shift toward more efficient and sustainable industrial practices.

Sealless pumps have emerged as crucial components across various industrial applications, primarily due to their unique design that eliminates the need for mechanical seals. This innovative approach reduces the risk of leakage, which is critical in processes involving hazardous or corrosive fluids. By minimizing environmental hazards and enhancing operational safety, sealless pumps play an essential role in industries such as chemical processing, food and beverage, and water treatment. Their ability to effectively handle a wide range of fluids, including viscous and shear-sensitive materials, further underscores their significance in industrial settings.

In addition to their safety benefits, sealless pumps are known for their superior efficiency and reliability. The absence of seals eliminates wear and tear associated with traditional pumping methods, leading to reduced maintenance requirements and operational downtime. Furthermore, sealless pumps often provide consistent flow rates and pressure stability, which are vital for maintaining process integrity. As industries increasingly prioritize efficiency and sustainability, the adoption of sealless pumps continues to rise, reflecting a growing recognition of their industrial importance and versatility.

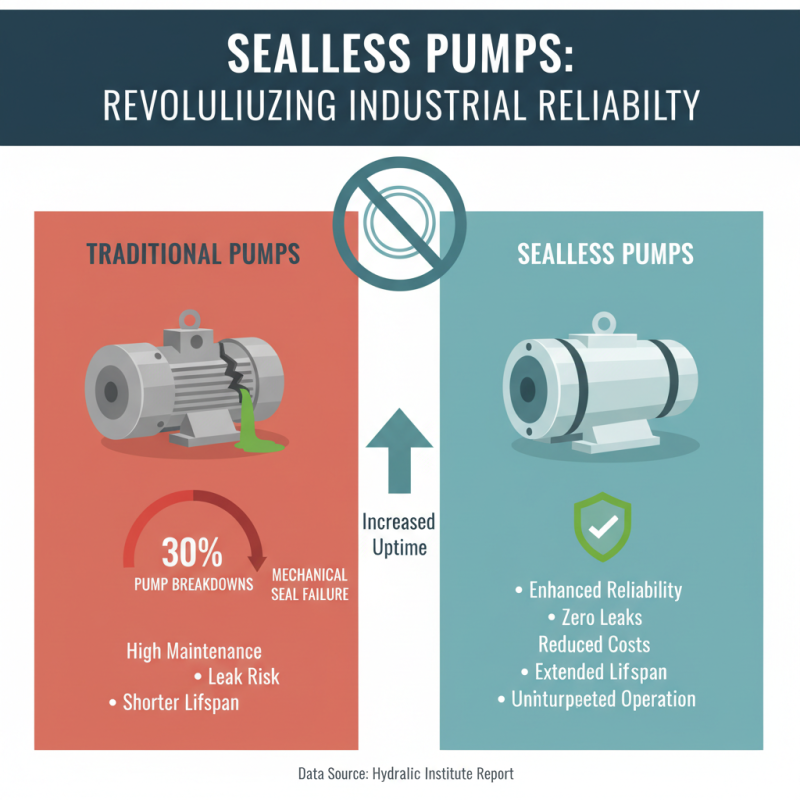

Sealless pumps have emerged as a revolutionary solution for industrial applications, delivering significant advantages over traditional pumping systems. One of the primary benefits is their enhanced reliability. According to a report by the Hydraulic Institute, mechanical seal failure is responsible for approximately 30% of all pump breakdowns. Sealless pumps, by design, eliminate the need for seals, thereby significantly reducing the risk of leaks and mechanical failures. This not only results in lower maintenance costs but also extends the operational lifespan of the pumping system, allowing industries to enjoy uninterrupted operations.

In addition to reliability, sealless pumps offer superior efficiency, especially in handling hazardous or volatile fluids. As per a study published in the Journal of Industrial Engineering, sealless designs can achieve efficiency levels of over 85%, compared to traditional pumps which typically range between 70% to 80%. This increase in efficiency translates to lower energy consumption and reduced operational costs, making sealless pumps an economical choice for many industrial settings. Moreover, their ability to manage a variety of fluids, including corrosive materials, without the risk of contamination further highlights their versatility and effectiveness, proving them to be indispensable in sectors such as chemical processing and pharmaceuticals.

Sealless pumps have emerged as a revolutionary alternative to traditional pump technologies, particularly due to their innovative design that eliminates the need for seals. This design feature significantly reduces the risk of leaks, which is a major concern in industrial applications. In contrast, traditional pumps often rely on various sealing methods that can wear down over time, leading to maintenance challenges and the potential for fluid loss, which can be both costly and environmentally damaging. The absence of seals in sealless pumps means they are less prone to wear and tear, resulting in longer operational life and reduced downtime for maintenance.

Additionally, sealless pumps typically offer superior efficiency in terms of energy consumption. Traditional pumps can suffer from energy losses associated with seal friction and wear, which can lead to higher operational costs. Sealless pumps, on the other hand, are designed to minimize these losses, providing smooth and efficient fluid transfer with lower energy input. This efficiency not only enhances overall system performance but also contributes to a more sustainable approach to energy use in industrial settings. As industries continue to seek ways to optimize their operations, the comparison between sealless pumps and traditional technologies clearly highlights the advantages of adopting sealless designs for improved efficiency and reliability.

| Feature | Sealless Pumps | Traditional Pumps |

|---|---|---|

| Leak Prevention | Excellent | Moderate |

| Maintenance Requirements | Low | High |

| Operational Efficiency | High | Moderate |

| Temperature Range | Wide | Limited |

| Cost Efficiency | Initial higher cost, long term savings | Lower initial cost, higher long-term maintenance |

| Fluid Handling Capability | Excellent for corrosive & volatile fluids | Good, but with limitations |

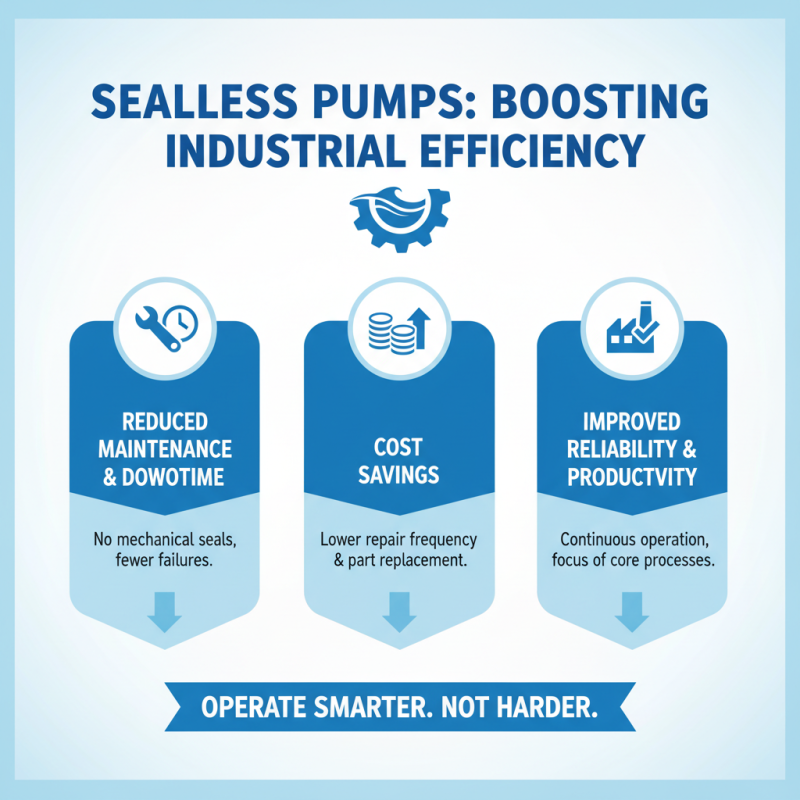

Sealless pumps have gained significant attention in industrial applications due to their ability to enhance operational efficiency and reduce costs. One of the most notable benefits of these pumps is the elimination of mechanical seals, which are a common failure point in traditional pumping systems. By removing seals, sealless pumps minimize maintenance requirements and downtime, allowing facilities to operate more smoothly and uninterrupted. This reliability translates into improved productivity, as operators can focus on core processes rather than dealing with frequent repairs or part replacements.

Moreover, the design of sealless pumps contributes to greater energy efficiency. These pumps often employ magnetic drive mechanisms that reduce the need for energy-intensive components. As a result, they consume less power during operation, leading to lower utility bills. The reduction in energy usage not only cuts costs but also aligns with sustainability initiatives, which are increasingly important in modern industrial practices. Additionally, the ability to handle various liquids, including corrosive and viscous fluids, without the risk of leaks further enhances their appeal as a cost-effective solution. Ultimately, the implementation of sealless pumps can lead to substantial improvements in operational performance and financial savings for industrial facilities.

Sealless pumps have gained traction across various industrial sectors due to their unique design that eliminates traditional packing seals. These pumps find applications in industries including chemical processing, pharmaceuticals, food and beverage, and water management. According to recent market insights, the sealless pump market is projected to grow at a CAGR of approximately 6% over the next five years, driven by the increasing demand for efficient and reliable fluid handling solutions.

In the chemical processing industry, sealless pumps are particularly beneficial for handling corrosive, volatile, or hazardous fluids. They minimize the risk of leakage, which can lead to environmental contamination and safety concerns. The U.S. Environmental Protection Agency (EPA) reports that improper handling of hazardous materials can result in significant economic and ecological damages, prompting industries to adopt safer fluid transfer methods. Furthermore, in the food and beverage sector, compliance with stringent hygiene standards is paramount. Sealless pumps, often made from sanitary materials, ensure the integrity of the product while reducing the risk of contamination during the pumping process.

In water management, sealless pumps enhance operational efficiency by reducing maintenance downtime associated with seal replacement. The Global Water Leader's 2022 report highlights that water utilities waste approximately 30% of treated water due to leakages, primarily from aging infrastructure. By integrating sealless pump technologies, utilities can achieve better fluid integrity and significantly lower their operational risks. The versatility and efficiency of sealless pumps make them an invaluable asset across various industries striving for sustainability and operational excellence.

This chart illustrates the key benefits of sealless pumps in various industrial applications, focusing on their efficiency, reliability, maintenance cost, environmental impact, and safety. The data shows that sealless pumps excel particularly in efficiency and safety, making them a strong choice for industrial use.