Sealless Pumps for a Safer and Greener World

In the realm of fluid management, sealless magnetic drive pumps are emerging as a pivotal technology, offering a robust solution for various industrial applications. These innovative pumps operate without traditional seals, effectively eliminating leakage and enhancing operational reliability. According to a report by MarketsandMarkets, the global market for magnetic drive pumps is projected to reach $4.12 billion by 2027, growing at a CAGR of 7.5%. This growth underscores the increasing demand for efficient and environmentally friendly pumping solutions across diverse industries.

Renowned industry expert Dr. Emily Novak, a leading researcher in pump technology, emphasizes the significance of sealless magnetic drive pumps, stating,

"The advancement in magnetic drive technology provides unparalleled safety and efficiency, particularly in handling corrosive and hazardous fluids."

This sentiment reflects the growing recognition of sealless designs as essential in sectors like chemical manufacturing, pharmaceuticals, and water treatment,

where leakage can pose serious risks.

As industries continue to seek innovative methods to enhance their fluid handling processes, understanding the benefits and applications of sealless magnetic drive pumps will be crucial. This article delves into their operational advantages, diverse applications, and the latest industry data, providing a comprehensive overview of this transformative technology.

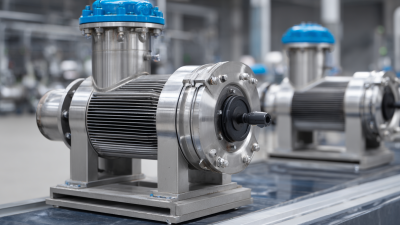

Seal-less magnetic drive pumps are innovative devices designed to transport fluids without the use of traditional mechanical seals. This technology relies on magnetic coupling to transfer rotational motion from the drive magnet outside the pump to the impeller inside, effectively eliminating the risk of leakage and reducing maintenance needs. As a result, these pumps are ideal for handling aggressive or hazardous liquids, as they prevent contamination and enhance safety in various industrial applications.

The design of seal-less magnetic drive pumps allows for operational efficiency and reliability. They are particularly beneficial in environments where traditional seals may wear out quickly due to abrasion or chemical exposure. Common applications include chemical processing, water treatment, pharmaceuticals, and food and beverage industries, where precision and cleanliness are paramount. By understanding the functionalities and advantages of seal-less magnetic drive pumps, industries can make informed decisions about implementing this technology to optimize their processes and mitigate environmental risks.

| Dimension | Value |

|---|---|

| Pump Type | Seal-less Magnetic Drive Pump |

| Key Benefit | Eliminates leakage of fluids |

| Applications | Chemical processing, pharmaceuticals, food and beverage |

| Efficiency Rating | Up to 80% efficiency |

| Typical Flow Rate | 0.5 to 1500 GPM |

| Temperature Range | -40°F to 300°F |

| Materials of Construction | Corrosion-resistant alloys, plastics |

| Maintenance Frequency | Low - Typically annually |

| Market Growth Rate | 5% CAGR over next 5 years |

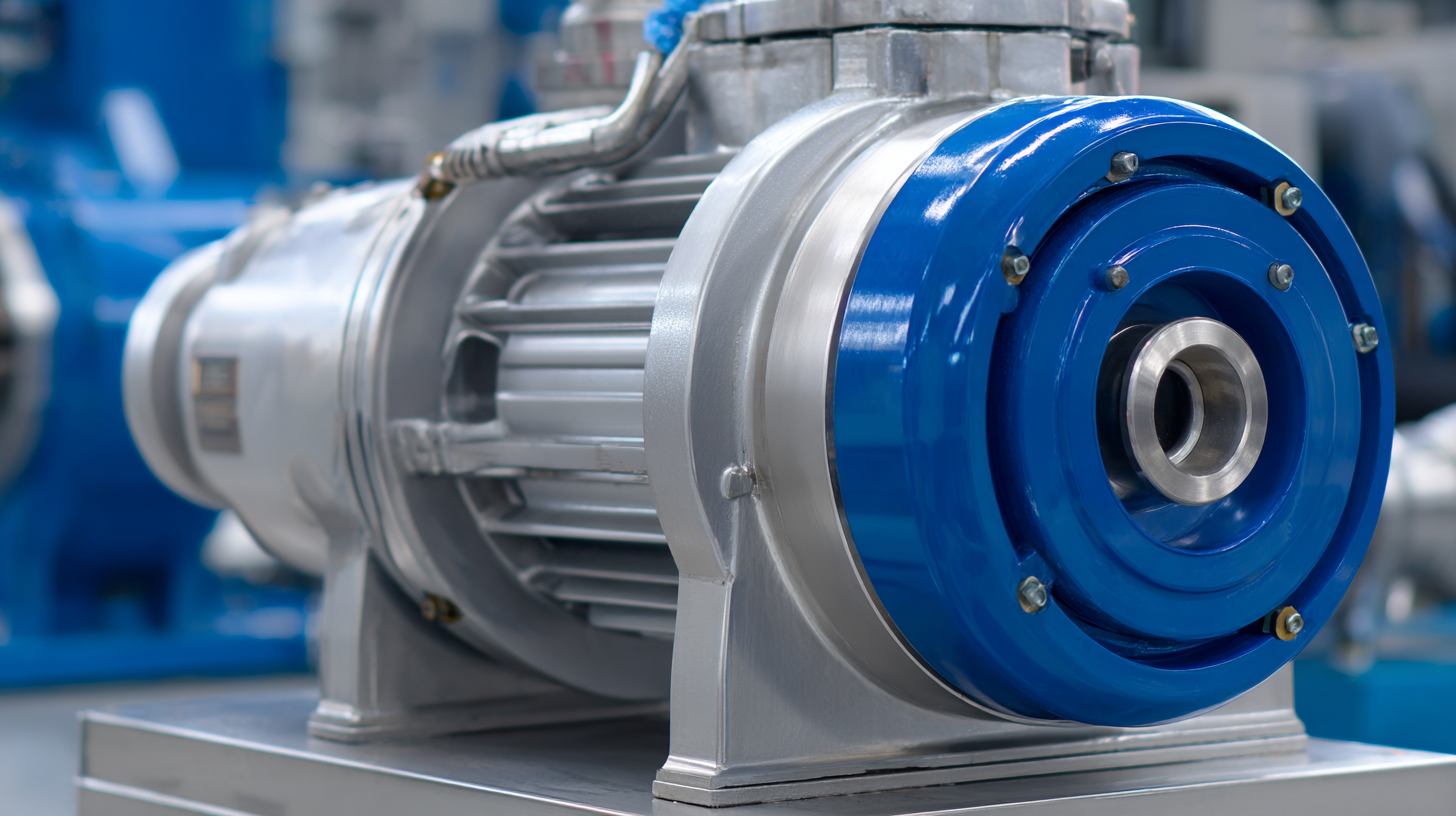

Seal-less magnetic drive pumps have gained popularity across various industries due to their unique design and numerous benefits. One of the primary advantages is their ability to operate without traditional mechanical seals, which eliminates the risk of leakage—a critical factor in sectors such as chemical processing and pharmaceuticals. According to a recent report by Global Market Insights, the magnetic drive pump market is projected to grow by over 8% annually through 2027, reflecting the increasing demand for reliable and maintenance-free pumping solutions.

Another significant benefit is the energy efficiency associated with seal-less magnetic drive pumps. They often use less power than traditional pumps, which can result in lower operational costs and a reduced carbon footprint. The U.S. Department of Energy highlights that energy-efficient pumps can save upwards of 30% on energy bills in industrial applications. Furthermore, these pumps excel in handling corrosive and volatile fluids, making them ideal for industries where fluid integrity is paramount, such as food and beverage, water treatment, and petrochemicals. This combination of efficiency, safety, and reliability positions seal-less magnetic drive pumps as a preferred choice in today’s industrial landscape.

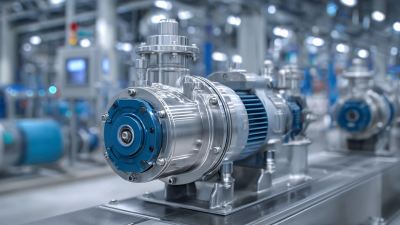

Seal-less magnetic drive pumps are increasingly gaining traction across various industries due to their unique design and operational benefits. These pumps are particularly effective in processes that require high efficiency and reliability, such as chemical processing, pharmaceuticals, and food manufacturing. By eliminating seals, they reduce the risk of leaks and contamination, making them ideal for handling toxic or hazardous materials. In the chemical industry, for example, where corrosive liquids are common, the use of seal-less pumps enhances safety and minimizes environmental risks.

Another critical application of seal-less magnetic drive pumps is in water treatment and wastewater management. Their ability to operate without traditional seals means less maintenance and reduced downtime, which is vital for facilities that need to ensure a continuous flow of water. Additionally, these pumps are increasingly used in HVAC systems and aquaculture due to their energy efficiency and quiet operation. As industries continue to prioritize sustainability and operational efficiency, seal-less magnetic drive pumps are becoming a standard choice for reliable fluid handling, showcasing their versatility across various sectors.

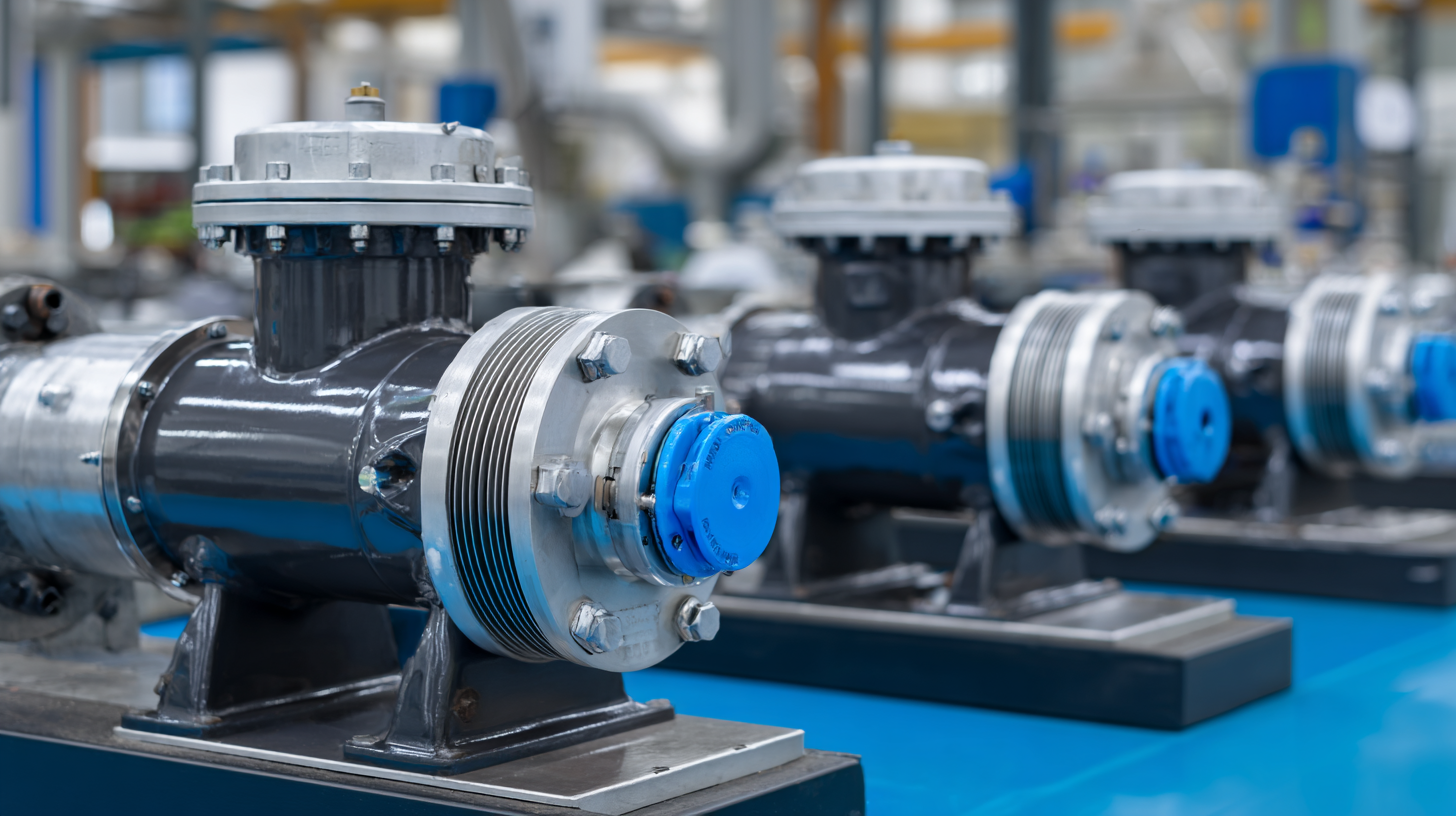

The seal-less magnetic drive pump sector is experiencing significant growth as industries increasingly recognize the advantages these systems offer. According to a recent industry report by Grand View Research, the global magnetic drive pump market is projected to reach USD 4.5 billion by 2026, expanding at a compound annual growth rate (CAGR) of 4.7%. This growth is driven by the demand for leak-free solutions in sectors such as chemical processing, pharmaceuticals, and food and beverage production, where product integrity and safety are paramount.

The benefits of seal-less magnetic drive pumps include reduced maintenance costs and increased efficiency, as these pumps eliminate the wear associated with traditional mechanical seals. A study by Research and Markets indicates that the adoption of these pumps can lead to operational efficiencies that reduce energy consumption by up to 33%. As industries become more focused on sustainability, the environmental benefits of minimizing leaks and spills also contribute to the rising popularity of magnetic drive systems.

Tip: When considering a seal-less magnetic drive pump for your application, assess the specific fluid properties and operational requirements to ensure compatibility and optimal performance. Consult with manufacturers for tailored solutions that meet your industry standards.

Seal-less magnetic drive pumps have gained significant traction in various industries due to their enhanced reliability and efficiency compared to traditional pump systems. Unlike conventional pumps that rely on mechanical seals which are prone to wear and leaks, seal-less magnetic drive pumps utilize magnetic fields to transfer motion, eliminating the need for seals altogether. This innovation results in much lower maintenance costs; studies show that maintenance expenses can be reduced by as much as 50%, making them a more cost-effective solution over time.

When comparing seal-less magnetic drive pumps to traditional systems, one must consider factors such as energy consumption and environmental impact. Research published in the Journal of Fluid Engineering indicates that magnetic drive pumps can achieve up to 90% energy efficiency, whereas traditional pumps often run at around 70%. Additionally, the absence of leaks reduces the risk of environmental contamination, making these pumps an eco-friendlier option for industries such as chemicals, pharmaceuticals, and food processing.

Tips: When selecting a pump system, always evaluate the lifecycle costs and potential maintenance issues. Also, consider how the pump's efficiency can affect your operational costs—opting for a seal-less magnetic drive pump could yield significant savings in the long run. Lastly, consult with industry experts to ensure you choose a solution tailored to your specific application needs.

This chart illustrates the comparative advantages of Seal-less Magnetic Drive Pumps over Traditional Pump Systems in various dimensions such as Efficiency, Maintenance, Cost-Effectiveness, and Reliability.