Sealless Pumps for a Safer and Greener World

A pressure pump is a vital device in various industries. It plays a crucial role in fluid movement and pressure regulation. According to the Global Market Insights report, the pressure pump market is expected to grow significantly, reaching $20 billion by 2026. This growth highlights the importance of understanding how pressure pumps function.

Pressure pumps work by converting mechanical energy into fluid pressure. They are widely used in agriculture, water supply systems, and industrial applications. For example, they help deliver water in irrigation systems, ensuring crops receive adequate hydration. However, not all systems are designed efficiently, which can lead to energy waste and increased operational costs.

Many users overlook the maintenance of pressure pumps, leading to performance issues. Studies indicate that regular servicing can improve efficiency by 15-30%. Choosing the right pump type and size is essential for optimal performance. Miscalculations can result in underperformance or over-pressurization, causing damage. It’s crucial for industries to analyze their needs carefully. Understanding pressure pumps better can lead to enhanced efficiency and sustainability across various applications.

A pressure pump is a vital device in various industries. Its primary purpose is to move fluids through a system by increasing fluid pressure. This function is crucial in applications such as irrigation, water supply, and industrial processes. According to industry reports, the global pressure pump market is expected to grow by 5% annually, indicating high demand across sectors.

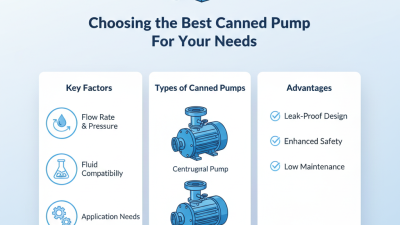

These pumps often utilize mechanical actions to achieve desired pressures. The design can vary, from positive displacement pumps to centrifugal models. For instance, a centrifugal pump creates pressure through the rotational energy of an impeller. This design is efficient but can be prone to cavitation, which may reduce performance. Many operations overlook the risk of cavitation, leading to costly downtime.

Additionally, pressure pumps play a key role in ensuring safety and efficiency. They help maintain consistent pressure levels in pipelines, reducing the chance of leaks or bursts. However, improper installation or lack of maintenance can lead to issues. A study indicated that nearly 30% of pump failures are due to improper maintenance practices. This statistic highlights the importance of regular checks and adjustments in any system relying on pressure pumps.

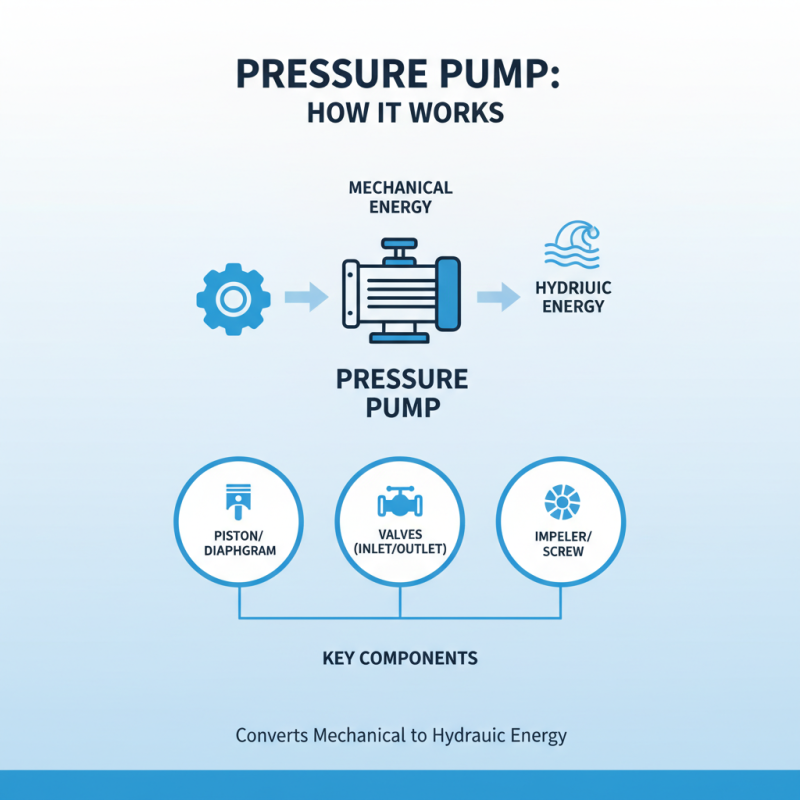

A pressure pump is vital in many applications. It functions by converting mechanical energy into hydraulic energy. Some key components enable this process effectively.

The motor powers the pump. It drives the impeller, which creates a flow of liquid. The impeller's design affects efficiency. The casing holds the impeller in place and contains the fluid. Both components must be durable to prevent leaks.

The inlet and outlet valves are crucial. They control fluid entry and exit. A poorly working valve can disrupt the entire system. Additionally, pressure gauges measure the system's performance. Regular checks on these components can prevent failures. Each part plays a role in maintaining pressure. Understanding these elements is essential for optimal operation.

A pressure pump is a vital component in various industrial systems. It increases the pressure of a fluid, enabling efficient fluid transfer. Understanding how a pressure pump operates helps optimize usage.

Pressure pumps work by converting input energy into hydraulic energy. This process involves the mechanical movement of a rotating element, which creates suction and pushes the fluid through the system. According to industry data from the Hydraulic Institute, many pumps operate efficiently within a range of 50% to 85% of their best efficiency point (BEP). Selecting the right pump size is crucial for optimal performance.

Tip: Always ensure that pump components are well-maintained. Regular inspections can identify signs of wear or corrosion that may affect performance.

For an effective operation, consider factors like flow rate and discharge pressure. Disregarding these can lead to inefficiency. Excessive pressure can cause leaks, while insufficient pressure may hinder flow. Additionally, energy costs can skyrocket if the pump operates outside its optimal range.

Tip: Monitor energy usage regularly to identify unexpected spikes. Identifying issues early can save costs long-term.

This bar chart illustrates the flow rate performance of different pressure pumps. Each pump's flow rate is measured in liters per minute (L/min), showcasing their efficiency and capability in transferring fluids effectively.

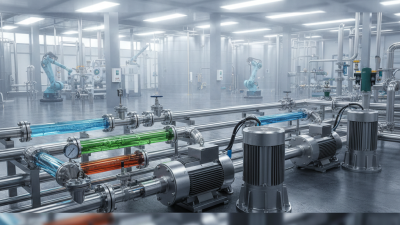

Pressure pumps play an essential role in many industries. These devices increase the pressure of liquids to ensure they flow efficiently. In agriculture, pressure pumps help irrigate crops. They move water from wells or reservoirs to fields. Farmers rely on them for healthy crop production. The precision of these pumps is vital for resource management.

In the construction industry, pressure pumps supply water for mixing concrete and other materials. Constant flow is necessary for creating strong structures. Without adequate pressure, projects can slow down or even halt. Many sites also use pressure pumps to remove water from excavations. This process keeps the areas dry and safe for work.

Despite their benefits, pressure pumps are not without challenges. Regular maintenance is crucial, yet often overlooked. Neglect can lead to inefficiencies or breakdowns. Operators should routinely check for leaks or malfunctions. Understanding these issues can help minimize risks. Each application highlights the need for reliable equipment in our daily lives.

Pressure pumps are vital for various applications, but like any machine, they require maintenance. Regular checks can help identify issues before they escalate. Start by inspecting the pump for any signs of wear and tear. Listen for unusual noises during operation. These sounds may indicate a problem that needs to be addressed.

Another crucial aspect of maintenance is changing the fluid regularly. Stale or contaminated fluid can harm the pump’s internal components. Check the seals and connections for leaks. A tiny leak can lead to significant drops in performance over time. Don’t overlook the power supply. Fluctuating voltage can affect pump efficiency.

If the pump fails to start, check the power source first. Sometimes, it’s as simple as a blown fuse or tripped circuit. If the pump runs noisily, it may need lubrication. Remember, every pump has its quirks. Some might work well for years, while others may require more attention. Identifying these patterns is key to effective troubleshooting.