Sealless Pumps for a Safer and Greener World

In recent years, the canned pump has emerged as a pivotal technology in various industrial applications, demonstrating remarkable efficiency and reliability. According to a report by Research and Markets, the global market for canned pumps is anticipated to reach $1.5 billion by 2025, growing at a compound annual growth rate (CAGR) of 7.3%. This surge in demand can be attributed to their ability to handle corrosive and abrasive fluids safely, as well as their compact design that allows for easy installation in tight spaces.

Canned pumps are characterized by their sealed structure, which helps prevent leaks and reduces maintenance costs. A study conducted by the International Pump Industry Association found that implementing canned pumps in industrial operations can lead to a 30% reduction in total lifecycle costs compared to traditional pumping systems. This innovation not only enhances operational efficiency but also significantly contributes to sustainability efforts by minimizing the environmental impact of fluid handling processes.

As industries continue to evolve, the application of canned pumps spans across sectors such as chemical processing, pharmaceuticals, and wastewater management. Their unique design and operational advantages place them at the forefront of modern fluid mechanics, leading to a transformation in how businesses approach pumping solutions. This article will explore the recent innovations and applications of canned pumps, showcasing their essential role in advancing industrial capabilities and performance.

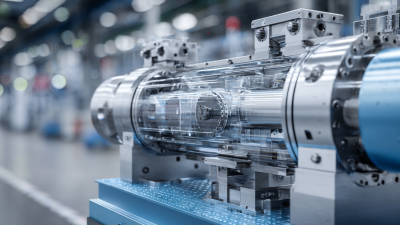

The evolution of canned pump technology has been pivotal in enhancing efficiency and reliability across various industries. Initially developed to address the challenges of maintaining fluid integrity and safety, these pumps have significantly progressed from basic designs to advanced models that cater to complex industrial needs. The integration of advanced materials and sealing technologies has allowed canned pumps to handle aggressive fluids and high temperatures, making them ideal for sectors such as chemical processing, pharmaceuticals, and oil and gas.

As industries continue to strive for sustainability and lower operational costs, canned pumps are becoming essential in energy conservation efforts. Their design minimizes leakage and ensures secure containment of hazardous substances, thereby reducing environmental risks. Furthermore, the advent of smart technology has enabled real-time monitoring and predictive maintenance, allowing for optimized performance and reduced downtime. The adaptability of canned pumps in various applications—from closed-loop systems in power generation to cooling systems in manufacturing—highlights their critical role in modern industrial operations.

Canned pumps have emerged as a revolutionary alternative to traditional pumping systems, primarily due to their innovative design that significantly reduces leaks and maintenance needs. One of the most critical benefits of using canned pumps is their ability to handle hazardous fluids without risking contamination or exposure. This is particularly valuable in industries such as petrochemical, pharmaceuticals, and food processing, where product purity is paramount. The self-contained nature of canned pumps ensures that operations run smoothly and efficiently, minimizing downtime from repairs.

Tips: When considering the transition to canned pumps, assess the specific fluid characteristics and operational conditions. This will help in selecting a pump that optimizes performance and longevity. Additionally, integrating canned pumps can lead to reductions in energy costs due to their efficient design, which is a considerable advantage for companies looking to improve their bottom line.

Another significant advantage of canned pumps is their compact design, which allows for easier installation in confined spaces. This is particularly beneficial in modern industrial settings where space can be a premium. Furthermore, the lower vibrations and noise levels associated with canned pumps contribute to a more conducive working environment, enhancing overall employee comfort and productivity.

Tips: Evaluate your facility layout to identify potential areas where canned pumps could replace larger, traditional pumping systems. Incorporating these pumps not only enhances safety but can also bolster your company's sustainable practices by reducing waste and improving resource efficiency.

Canned pumps, a significant advancement in pump technology, play a crucial role in the chemical processing industry. These pumps are designed with a sealed casing that encloses the impeller and motor, preventing any leakage of hazardous substances. This innovative design not only enhances safety but also ensures compliance with stringent environmental regulations. As chemical processing often involves toxic or corrosive fluids, the ability of canned pumps to operate without the risk of spills or vapors makes them an invaluable asset for manufacturers.

In addition to their safety benefits, canned pumps exhibit superior efficiency and reliability. They are capable of handling a wide range of fluid viscosities and temperatures, making them versatile for various chemical applications, from handling abrasive slurries to transporting volatile solvents. The reduced maintenance needs owing to their sealed nature translate into lower operational costs and less downtime. As industries continue to embrace sustainability and seek technology-driven solutions, the adoption of canned pumps is expected to increase, further solidifying their position as a preferred choice in modern chemical processing environments.

| Application Area | Type of Canned Pump | Flow Rate (L/min) | Pressure Range (bar) | Temperature Range (°C) | Material Compatibility |

|---|---|---|---|---|---|

| Chemical Processing | Magnetic Drive Pump | 100 | 5-10 | -20 to 100 | Acids, Alkalis |

| Pharmaceuticals | Canned Motor Pump | 50 | 3-8 | 0 to 150 | Biopharmaceuticals, Solvents |

| Food and Beverage | Sanitary Canned Pump | 200 | 1-5 | 0 to 80 | Sugars, Alcohols |

| Petrochemicals | Chemical Process Pump | 300 | 10-15 | -10 to 120 | Hydrocarbons |

| Wastewater Treatment | Vertical Canned Pump | 150 | 2-12 | 0 to 50 | Sewage, Chemicals |

Canned pumps have emerged as key players in promoting environmental sustainability across various industries. Unlike traditional pumps, canned pumps have a sealed design that minimizes the risk of leaks, thereby reducing the potential for chemical spills that could harm ecosystems. Their robust construction allows for efficient operation with reduced energy consumption, directly contributing to lower carbon emissions. By integrating canned pumps into industrial processes, companies can enhance their sustainable practices while ensuring the safe handling of hazardous fluids.

Tips for maximizing the environmental benefits of canned pumps include regular maintenance checks to ensure optimal performance and energy efficiency. Additionally, consider implementing a monitoring system to track the pump's output and energy usage, which can help identify areas for improvement. Organisations should also invest in training for staff on the proper operation of canned pumps to minimize waste and prevent operational mishaps.

Furthermore, the versatility of canned pumps extends their applicability beyond just fluid handling; they also play a significant role in waste water management and chemical processing, sectors critical to sustainability initiatives. By leveraging the advancements in canned pump technology, industries can not only enhance their efficiency but also contribute to a greener, more sustainable future.

The advancements in canned pump technology are paving the way for innovative designs and functionalities that meet the evolving demands of modern industries. One of the key future trends is the integration of smart technology within canned pumps. This includes the implementation of IoT (Internet of Things) capabilities, enabling real-time monitoring and predictive maintenance. Such innovations not only enhance operational efficiency but also reduce downtime, significantly benefiting sectors such as chemical processing and oil and gas.

Another significant development is the focus on sustainability in design. Manufacturers are increasingly prioritizing eco-friendly materials and energy-efficient systems to minimize the environmental impact of their products. Enhanced materials that resist corrosion and wear are being researched, which could extend the lifespan of these pumps and reduce the need for replacements. Additionally, the trend towards modularity allows for easier customization and adaptability to diverse applications, offering users more flexibility and efficiency in operations.