Sealless Pumps for a Safer and Greener World

In the realm of industrial processes, the significance of high pressure systems cannot be overstated. These systems play a crucial role in enhancing efficiency, optimizing production, and ensuring the safety of operations across various sectors. As industries strive to meet increasing demands for productivity and sustainability, understanding the benefits and applications of high pressure systems becomes essential. From chemical manufacturing to food processing, high pressure environments facilitate faster reactions, increase material throughput, and improve the overall quality of products.

Moreover, the integration of high pressure technologies into existing processes not only streamlines operations but also contributes to energy conservation and reduced waste. Industries are increasingly recognizing the competitive advantage of adopting high pressure systems, leading to their essential status in modern manufacturing and production lines. As we move towards the future, the exploration of innovative high pressure solutions will likely shape the landscape of industrial efficiency, making it imperative for businesses to stay ahead of the curve.

In this context, the article will delve into the top ten reasons why high pressure systems are vital for industrial processes, exploring both their technical advantages and their impact on moving towards a more efficient and sustainable industrial ecosystem. Understanding these facets will equip industry leaders and decision-makers with the knowledge to embrace high pressure systems as a cornerstone of their operational strategy.

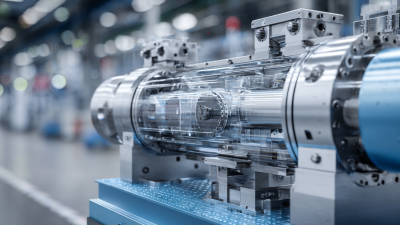

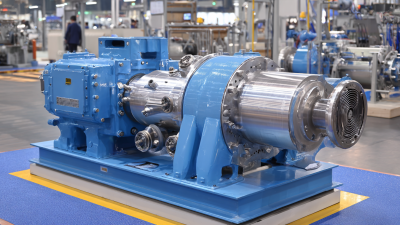

High pressure systems play a crucial role in enhancing industrial efficiency by optimizing various processes across multiple sectors. These systems enable the use of elevated pressure levels to improve the reaction rates in chemical processes, allowing manufacturers to produce higher yields of desired products in a shorter timeframe. For instance, in the petrochemical industry, high pressure is essential for reactions such as cracking, where increased pressure leads to more efficient conversion of feedstock into valuable products.

Moreover, high pressure systems contribute significantly to energy savings and sustainability. By operating at elevated pressures, equipment can achieve greater efficiency in processes such as combustion, where the improved air-fuel mixture results in more complete combustion and reduced emissions. This not only enhances overall energy use but also minimizes the environmental impact of industrial operations. Thus, implementing high pressure systems is not just about increasing productivity; it aligns with modern sustainability goals, making them indispensable in contemporary industrial practices.

High pressure systems play a pivotal role in enhancing industrial processes by facilitating efficient operations in various applications. A crucial component of these systems includes terminal isolation amplifiers. With the demand for electrical insulation rising, particularly in electric vehicle (EV) designs, the market for these amplifiers is projected to grow significantly. By 2033, the market size for terminal isolation amplifiers is expected to reach $220 million, a notable increase from $175 million in 2025, reflecting a compound annual growth rate (CAGR) of 2.9%. This growth underscores the increasing reliance on safe, high voltage connections in modern industrial settings.

In addition to isolation amplifiers, other key components of high pressure systems in industrial applications include control valves and advanced ceramics. Control valves serve as essential devices for regulating fluid flow and maintaining critical parameters such as pressure and temperature. With the global control valve market anticipated to expand, these devices are necessary for sustaining operational efficiency. Furthermore, advanced ceramics such as alumina and zirconia are being leveraged in high pressure scenarios due to their durability and resistance to harsh conditions. As industries continue to evolve, investing in these components will undoubtedly enhance the performance and reliability of high pressure systems across various sectors.

High pressure systems are becoming increasingly essential in the manufacturing sector, as they significantly enhance operational efficiency and product quality. The incorporation of such systems allows for higher processing temperatures and pressures, enabling faster reactions and reducing processing times. As the Adhesives & Sealants Market is projected to reach USD 140.9 billion with a CAGR of 6.2% from 2025 to 2035, the role of high pressure systems becomes even more pronounced in meeting this surge in demand while maintaining efficiency and cost-effectiveness.

To fully leverage the benefits of high pressure systems, manufacturers should consider implementing atmospheric plasma technology, which is proven to increase efficiency and reduce waste. Moreover, adopting digital twin technology can further optimize manufacturing processes by providing a virtual representation of operations, facilitating real-time monitoring and predictive analytics.

Tips for manufacturers looking to implement high pressure systems include investing in training for staff to handle these advanced technologies safely and effectively. Additionally, collaborating with technology providers can yield insights into best practices and innovative solutions tailored to specific production needs. By focusing on these strategies, businesses can ensure a smooth transition and maximize the advantages high pressure systems offer.

High pressure systems play a crucial role in enhancing the efficiency of industrial processes, but their implementation comes with unique challenges. One major obstacle is ensuring the integrity of the equipment used under high pressure conditions. Mechanical failure due to material fatigue can lead to dangerous accidents and costly downtime. To address this, investing in advanced materials and regular maintenance schedules is essential. Additionally, training staff on handling high pressure systems safely is critical in preventing operational mishaps.

Moreover, the environmental impact of these systems cannot be overlooked. High pressure operations often generate significant emissions and waste, contributing to air and water pollution. Employing systems thinking, industries can devise strategies to minimize their ecological footprint while maintaining operational efficiency. This involves integrating advanced technology for emissions monitoring and implementing closed-loop systems for resource management. By tackling these complexities with innovative solutions, industries can harness the benefits of high pressure systems while mitigating potential risks to both human health and the environment.

High pressure systems are becoming increasingly vital in industrial processes, driving efficiency and productivity to new heights. As we look toward the future, advancements in high pressure technologies present promising opportunities for industries seeking to optimize their operations. Recent reports indicate that the global high-pressure pump market is expected to grow by approximately 6.5% annually, propelled by innovations in materials and engineering that enhance system durability and energy efficiency. For instance, the introduction of smart sensors and IoT connectivity in high-pressure systems allows for real-time monitoring and predictive maintenance, significantly reducing downtime and operational costs.

Tips: To maximize the benefits of high-pressure technology, industries should stay updated on the latest advancements and invest in training for their workforce. This ensures not only proper implementation but also helps in harnessing the full potential of these systems in various applications.

In addition, advancements in high pressure processing (HPP) are revolutionizing the food and beverage sector. According to a recent industry analysis, the HPP market alone is forecasted to reach $3.2 billion by 2025, showcasing a growing preference for non-thermal food preservation methods. Such technologies not only improve product quality and shelf life but also align with consumer demands for healthier, minimally processed foods.

Tips: Considering energy consumption in the selection of high-pressure equipment can lead to substantial cost savings and contribute to sustainable practices within the industry.

| Dimension | Current Value | Projected Growth (2025) | Key Benefits |

|---|---|---|---|

| Market Size (USD Billion) | 15.2 | 22.5 | Increased productivity, Reduced operational costs |

| Adoption Rate (%) | 45 | 60 | Enhanced reliability, Improved safety standards |

| Energy Efficiency (%) | 80 | 92 | Reduction in energy costs, Decreased carbon footprint |

| Technological Innovations | Smart sensors | IoT integration | Real-time monitoring, Predictive maintenance |

| Key Industries | Manufacturing | Chemical processing | Improved process control, Better quality assurance |