Sealless Pumps for a Safer and Greener World

In the fast-evolving industrial landscape of 2023, the demand for high pressure pumps continues to surge, driven by their critical role in applications ranging from oil and gas extraction to chemical processing and water treatment. According to a recent market analysis by Research and Markets, the global high pressure pump market is projected to reach $18 billion by the end of this year, growing at a CAGR of 5.3%. This growth highlights the necessity for industries to invest in advanced pump technologies that enhance efficiency and reliability under demanding conditions.

Industry expert Dr. Martin L. Hartman, a leading mechanical engineer specializing in fluid dynamics, emphasizes the importance of selecting the right high pressure pump for specific industrial applications. He notes, "Choosing the appropriate high pressure pump can drastically impact operational efficiency and cost-effectiveness, making it essential for engineers to stay abreast of innovations and market trends." As industries continue to seek ways to optimize performance, understanding the diverse range of high pressure pumps available is paramount for meeting both operational goals and sustainability targets.

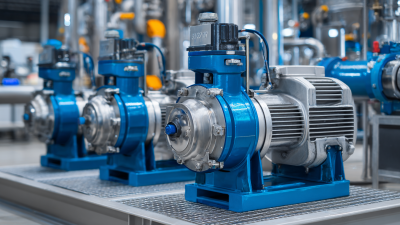

High pressure pumps are essential components in various industrial applications, providing the necessary force to move fluids at high pressures. These pumps are widely used in sectors such as oil and gas, chemical manufacturing, and water treatment, among others. Their ability to handle challenging liquids, including corrosive substances and slurries, makes them indispensable in maintaining efficient operational processes. The design of high pressure pumps must accommodate specific requirements such as flow rate, pressure control, and pump material to ensure optimal performance under demanding conditions.

In industrial settings, high pressure pumps facilitate numerous functions, from powering hydraulic systems to enabling advanced cleaning processes. For instance, they are critical in the hydraulic fracturing process in energy extraction, where fluids must be injected at high pressures to create fractures in rock formations. Similarly, in manufacturing, these pumps are used for spraying and applying coatings or chemicals, ensuring uniform distribution and coverage. Their robust design and efficiency not only enhance productivity but also contribute to the safety and reliability of various industrial operations. As industries continue to evolve, the demand for high pressure pumps is expected to grow, driven by advancements in pump technology and increasing industrial requirements.

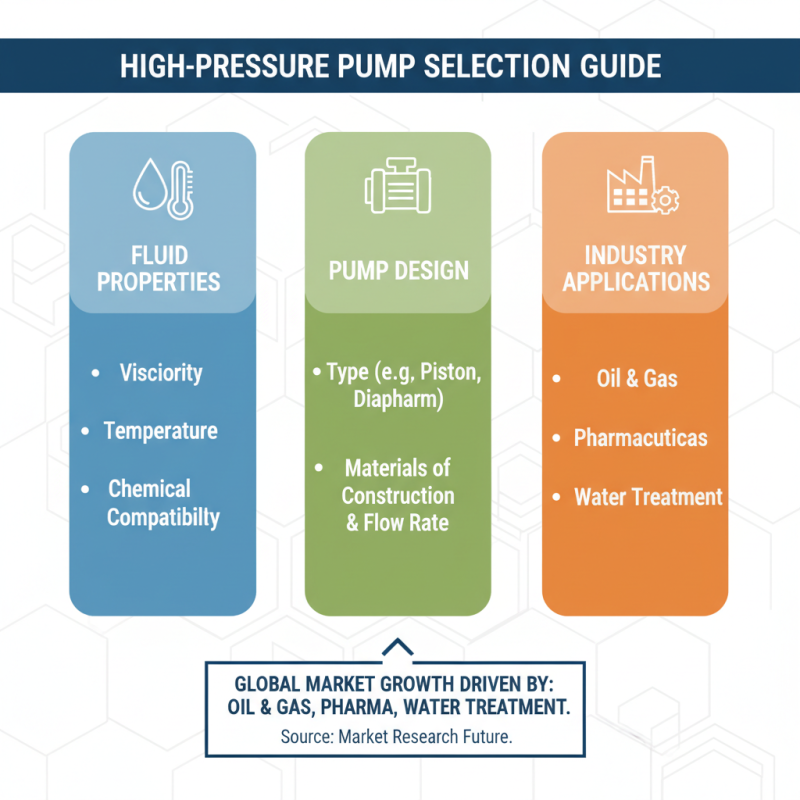

When selecting a high pressure pump for industrial applications, several critical factors should be considered to ensure optimal performance and efficiency. First, understanding the fluid properties, including viscosity, temperature, and chemical compatibility, is crucial. Different pumps are designed to handle specific types of fluids; thus, selecting a pump that matches the fluid characteristics will minimize wear and prolong the pump’s lifespan. According to a recent industry study by Market Research Future, the global high pressure pump market is projected to grow significantly due to increased demand in sectors such as oil and gas, pharmaceuticals, and water treatment.

Another essential consideration is the pump's flow rate and pressure rating. Evaluating the required flow rates for your specific application helps in selecting a pump that can handle the operational demands without straining. Higher pressure ratings can often indicate a more robust design but may also involve higher operational costs. It’s beneficial to consult resources such as the Hydraulic Institute’s standards, which outline best practices for pump selection to align with your operational needs.

**Tips:** When assessing pump options, consider conducting a lifecycle cost analysis that encompasses installation, operation, and maintenance costs. Additionally, ensure that the chosen pump complies with industry standards and best practices to prevent future operational challenges. Regular maintenance schedules should also be established to uphold efficiency and performance over time.

When it comes to industrial applications, the demand for high pressure pumps varies significantly across different sectors. The global high pressure pumps market was valued at approximately $4.5 billion in 2022 and is projected to grow at a CAGR of 6.4% from 2023 to 2030, according to a recent report by Market Research Future. This growth is primarily driven by the increasing need for efficient fluid transfer in industries such as oil and gas, petrochemicals, and manufacturing. Each application requires specific pump characteristics, which can influence the selection process significantly.

For instance, in the oil and gas sector, pumps must not only handle high pressures but also be resistant to corrosive materials and extreme temperatures. A report by Transparency Market Research highlights that the need for innovative designs in pumps to mitigate issues like wear and tear under high pressure is critical for maintaining operational efficiency. Conversely, in water treatment and industrial cleaning applications, high pressure pumps are utilized for their ability to deliver high flow rates with minimal energy consumption. The choice of materials and design can drastically affect the performance and longevity of the pump, emphasizing the necessity to tailor pump solutions to specific industrial needs.

| Pump Type | Max Pressure (psi) | Flow Rate (GPM) | Power Source | Applications |

|---|---|---|---|---|

| Diaphragm Pump | 3000 | 12 | Electric | Chemical Processing |

| Centrifugal Pump | 2000 | 50 | Diesel | Water Supply |

| Gear Pump | 1500 | 25 | Hydraulic | Fuel Transfer |

| Piston Pump | 4000 | 10 | Electric | Oil & Gas |

| Submersible Pump | 2500 | 40 | Electric | Wastewater |

| Progressing Cavity Pump | 3500 | 15 | Electric | Food Industry |

| Triplex Pump | 4500 | 20 | Hydraulic | Mining |

| Vacuum Pump | 1000 | 5 | Electric | Laboratory |

| Lobe Pump | 2000 | 30 | Electric | Cosmetics |

| Rotary Vane Pump | 1200 | 8 | Electric | Vacuum Systems |

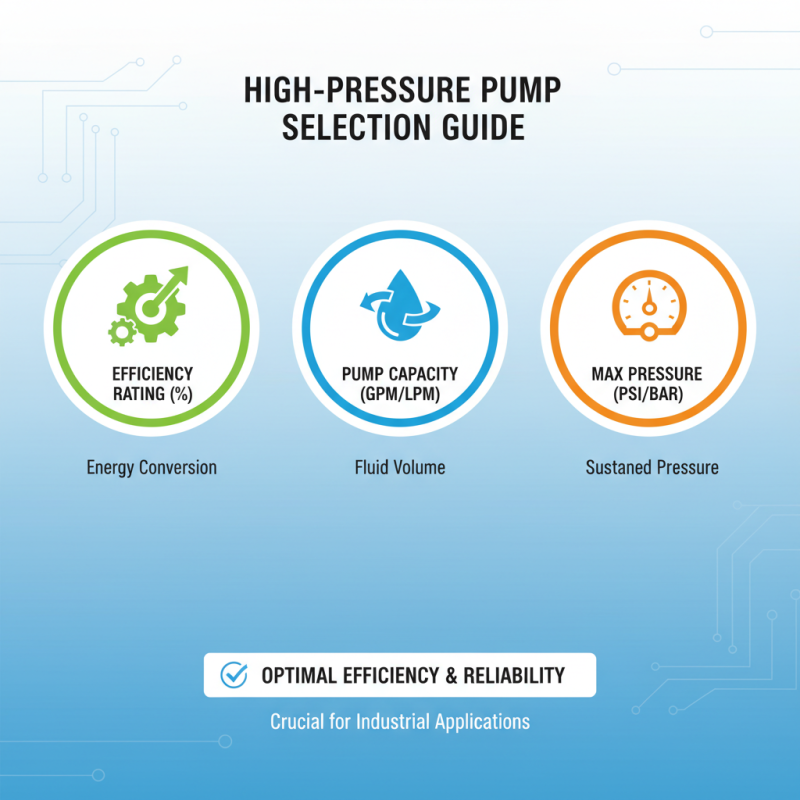

When selecting high-pressure pumps for industrial applications, it's crucial to assess various specifications and performance metrics to ensure optimal efficiency and reliability. Efficiency ratings, often expressed as a percentage, can indicate how well a pump converts input energy into hydraulic energy. Pump capacity, measured in gallons per minute (GPM) or liters per minute (LPM), reveals the volume of fluid a pump can move and is essential for meeting the demands of specific processes. Additionally, the maximum pressure rating, typically listed in PSI or bar, defines the highest pressure the pump can sustain, which is particularly important for industries dealing with highly viscous materials or requiring stringent output pressures.

Another vital aspect of pump specifications is the material of construction, which can influence durability and corrosion resistance, especially when handling abrasive or corrosive fluids. The design of the pump, whether it's a centrifugal or positive displacement model, also plays a role in determining its performance characteristics such as flow pulsation, maintenance needs, and overall lifecycle costs. Moreover, considering the energy consumption and operational noise levels can contribute to a more sustainable and comfortable working environment. By carefully comparing these specifications, industries can make informed decisions in selecting the right high-pressure pump that aligns with their operational requirements and performance goals.

Maintaining high pressure pumps is crucial for ensuring their longevity and optimal performance in industrial applications. Regular inspection and routine maintenance can significantly reduce the risk of unexpected breakdowns and prolong the lifespan of these essential machines. A consistent maintenance schedule should include checking for leaks, ensuring all fittings are secured, and examining seals and gaskets for wear. Additionally, operators should monitor the pump's vibration levels and temperature to detect any anomalies early, as these could signal impending issues.

Another key aspect of maintenance involves the lubrication of moving parts. Proper lubrication minimizes friction and wear, effectively extending the life of the pump. Always refer to the manufacturer’s guidelines for the appropriate type of lubricant and intervals for application. Furthermore, it is essential to keep the pump clean and free from debris that can impair performance. Regularly flushing the system helps to remove contaminants that may accumulate and cause damage over time. By prioritizing these maintenance practices, industrial facilities can ensure their high pressure pumps operate efficiently and reliably for years to come.

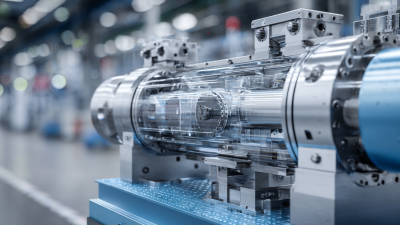

This chart represents the performance metrics of the top 10 high-pressure pumps in 2023, focusing on flow rate (GPM) and maximum pressure (PSI). These insights will help you choose the right pump for your industrial needs.