Sealless Pumps for a Safer and Greener World

Selecting the right industrial centrifugal pumps can significantly impact operational efficiency. The global pump market is projected to exceed $65 billion by 2026, according to recent industry reports. As industries focus on sustainability and performance, choosing the proper pump is crucial.

Understanding the specific requirements of your application is vital. Factors like flow rate, pressure, and medium characteristics demand attention. The wrong choice can lead to costly maintenance and operational downtime. Reports indicate that improper pump selection can increase energy costs by up to 30%.

Investing time in research and consultation will pay off. An ideal industrial centrifugal pump balances efficiency and durability. This investment is crucial, given the potential losses from malfunctioning equipment. Almost 25% of pumps are not operating at their best efficiency point, highlighting the need for careful selection.

Industrial centrifugal pumps play a crucial role in various applications. They are designed to transfer fluids efficiently. Understanding their basic operation is key to making an informed choice. When selecting a pump, consider the fluid properties. Is it viscous, abrasive, or corrosive? Each characteristic demands a specific pump design.

Pump capacity is another vital factor. Calculate the required flow rate and head. Failure to do so can lead to issues. High flow rates may lead to cavitation, causing damage. Low flow rates can result in inefficient operations. The material of the pump casing also matters. It must withstand pressure and chemical interactions.

Another point to think about is maintenance. Some pumps require more upkeep than others. Regular checks and service are essential. Neglecting this can shorten pump life. While it's tempting to choose the flashy model, reflect on your needs. A simple design may offer better reliability. Prioritize performance over brand reputation and appearance.

When selecting industrial centrifugal pumps, various key factors come into play. Understanding fluid characteristics is paramount. For instance, viscosity, temperature, and density can impact pump performance. Research shows that about 70% of pump failures stem from improper selection based on fluid properties. This statistic highlights the importance of accurate fluid analysis.

Another critical aspect is the required flow rate and pressure. The right pump should meet operational needs without excessive energy consumption. According to industry reports, optimizing these parameters can improve efficiency by 15% to 20%. Engineers must calculate both the total dynamic head and the net positive suction head accurately. Small miscalculations can lead to cavitation, causing significant damage over time.

Material compatibility should not be neglected. Corrosive fluids may require more robust materials. A recent survey indicated that 30% of pump failures result from material degradation. This can lead to increased maintenance costs and unplanned downtimes. Therefore, careful material selection and regular inspections are necessary to ensure long-term reliability.

When selecting an industrial centrifugal pump, understanding performance and capacity is crucial. Many industry reports indicate that up to 30% of pump failures are related to improper sizing. A pump that is too small will struggle to keep up with demand. Conversely, an oversized pump can lead to inefficiencies and increased energy costs.

Performance metrics often include flow rate and head. A flow rate that doesn't match your system's requirements will lead to disruption. For example, if a facility requires 500 gallons per minute (GPM) but the chosen pump only provides 300 GPM, production can halt. On the other hand, the head pressure needs careful assessment. Insufficient head can prevent fluid from reaching the desired location. Data from the Hydraulic Institute suggests that miscalculating head requirements can also lead to costly operational issues.

Consider the fluid characteristics, too. The viscosity, temperature, and corrosiveness influence pump effectiveness. A pump may perform well under standard conditions but falter with non-standard fluids. This need for adaptability is often overlooked. Many engineers focus on initial performance and neglect long-term operational costs. Emphasizing a comprehensive evaluation can prevent future setbacks and enhance reliability.

| Tip | Description | Performance Indicator | Capacity Requirement (GPM) |

|---|---|---|---|

| 1. Assess Fluid Characteristics | Evaluate viscosity, temperature, and chemical compatibility. | Viscosity (cP) | 100 GPM |

| 2. Determine System Head Requirements | Calculate total dynamic head to ensure pump selection fits system. | Total Dynamic Head (TDH) | 150 Feet |

| 3. Establish Required Flow Rate | Identify necessary flow rate based on process needs. | Flow Rate (GPM) | 200 GPM |

| 4. Consider Pump Material | Select materials that resist corrosion and wear for longevity. | Material Type | Stainless Steel |

| 5. Evaluate Efficiency Ratings | Look for high efficiency to minimize operational costs. | Pump Efficiency (%) | 85% |

| 6. Examine Maintenance Needs | Choose pumps that require minimal maintenance for ease of use. | Maintenance Frequency (months) | 6 Months |

| 7. Assess Noise Levels | Consider pumps with lower noise ratings for a quieter operation. | Noise Level (dB) | 75 dB |

| 8. Check Pump Size and Footprint | Verify the space available for installation matches pump dimensions. | Footprint (sq. ft.) | 10 sq. ft. |

| 9. Verify Regulatory Compliance | Ensure pumps meet relevant industry standards and regulations. | Compliance Standards | ISO 9001 |

| 10. Seek Trusted Suppliers | Work with reputable suppliers for reliable support and service. | Supplier Rating | 4.5/5 |

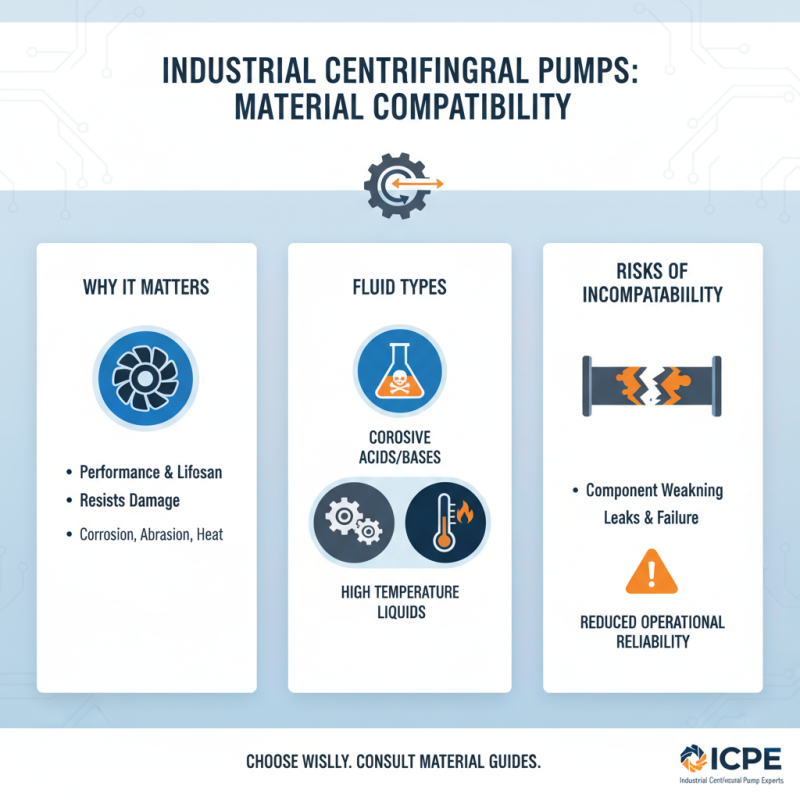

When selecting industrial centrifugal pumps, evaluating material compatibility is crucial. The construction materials directly affect performance and lifespan. Pumps may encounter various fluids, including corrosive substances, abrasives, and high temperatures. If the materials are incompatible, issues may arise. Corrosion can weaken components quickly.

Consider the specific application when choosing materials. For example, stainless steel is often a good choice for chemical applications. However, it may not be the best option for abrasive slurries. Another tip is to check the compatibility table provided by manufacturers. This guide helps identify suitable materials for various fluids. When in doubt, consult with an expert. They can provide insights on material performance under specific conditions.

It’s important to remember that not all materials behave the same way. Sometimes, what seems like a minor detail can lead to significant failures. For instance, plastic components can seem cost-effective, but their durability may suffer. Always factor in the long-term costs of materials. While the initial investment is important, look at the overall lifecycle costs. This approach ensures better decisions in the long run.

When it comes to industrial centrifugal pumps, maintenance is key for long-term performance. Regular inspections can help detect wear and tear early. Checking for leaks should be a routine task. Identifying issues before they become major problems saves time and money. Pump seals may degrade over time. Replacing them promptly ensures efficiency.

Service needs can vary based on the pump's environment. Some pumps operate in challenging conditions. Dust, moisture, or chemicals can accelerate wear. A maintenance kit tailored to these conditions can be beneficial. Consider creating a service schedule. Marking the calendar helps avoid overlooked maintenance. Documenting each service can provide insights into performance.

Operators sometimes underestimate how maintenance impacts lifespan. Ignoring signs of wear may lead to costly failures. Encouraging open communication among staff about maintenance issues is valuable. Cultivating a culture of proactive maintenance will enhance reliability. Regular training can keep everyone informed about best practices. Ultimately, it’s about investing in tools that ensure longevity.