Sealless Pumps for a Safer and Greener World

Choosing the right pump specialist is crucial for the success of any project that involves fluid transport, whether it be for industrial, agricultural, or municipal applications. The expertise and experience of a pump specialist can greatly influence not only the efficiency and reliability of your pumping system but also the overall cost and sustainability of your operations. As industries evolve and demands change, understanding how to select the appropriate pump specialist becomes an essential skill for project managers and engineers alike.

When embarking on a project requiring pumping solutions, it is imperative to consider several factors that can guide you to the right pump specialist. These include their technical knowledge, past project experience, and understanding of your specific needs and challenges. A competent pump specialist should be able to offer tailored solutions that align with your project objectives, ensuring that you receive the best possible advice and service. Furthermore, the ability to provide ongoing support and maintenance is a vital attribute of a quality pump specialist, which can contribute significantly to the longevity and performance of your pumping systems. By thoroughly evaluating these criteria, you will be better equipped to select a pump specialist who not only meets your requirements but also exceeds your expectations.

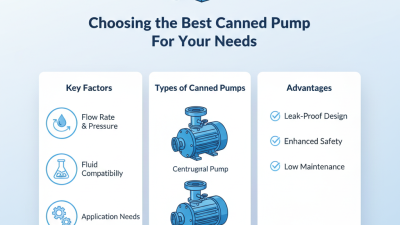

When embarking on any project that requires pumping solutions, it is essential to first identify your specific pump requirements. Whether you're dealing with transferring fluids in industrial settings or managing irrigation systems, understanding the nature of your application is crucial. According to a recent industry report, over 60% of pump failures can be attributed to inappropriate selection based on application needs. This statistic emphasizes that getting the right pump for your project can not only enhance efficiency but also extend the lifespan of the equipment.

In determining your pump needs, consider the type of fluid, flow rate, pressure, temperature, and the distance it needs to be transported. For instance, a heavy slurry may require a different pump type compared to clear water. Additionally, understanding the total dynamic head (TDH) is vital, as it affects the efficiency of the pump and energy consumption. Research shows that selecting a pump with optimal efficiency can reduce operational costs by up to 30% over its lifecycle.

**Tips:** First, create a project checklist that outlines all the requirements for your pumping system. Include factors like environmental conditions and compatibility with existing infrastructure. Secondly, consult with a specialist who can provide insights based on previous projects with similar needs, ensuring you have the right data to make an informed decision. Lastly, always ensure that the pumps are compliant with industry standards, as this can significantly impact performance and reliability.

| Pump Type | Application | Flow Rate (GPM) | Head Pressure (ft) | Efficiency (%) | Special Features |

|---|---|---|---|---|---|

| Centrifugal Pump | Water Supply | 50 | 100 | 85 | Self-priming |

| Submersible Pump | Sump Drainage | 30 | 50 | 80 | Automatic Float Switch |

| Positive Displacement Pump | Viscous Fluids | 20 | 40 | 90 | Variable Speed Drive |

| Diaphragm Pump | Chemical Transfer | 10 | 30 | 75 | Leak-proof Design |

When selecting a pump specialist for your projects, assessing their expertise and experience is crucial. According to the Hydraulic Institute, an organization that represents leading manufacturers in the pump industry, nearly 25% of all pump failures can be attributed to inadequate expertise during installation or maintenance. Therefore, it is essential to evaluate the qualifications of a pump specialist to ensure they possess the necessary knowledge to handle your specific requirements.

One effective approach is to inquire about the specialist's relevant industry experience. An expert with at least five years in a particular sector—such as wastewater, chemical processing, or oil and gas—is more likely to understand the unique challenges and requirements you may face. Additionally, checking for certifications from recognized organizations can give you confidence in their abilities. Reports have shown that companies working with certified specialists have a 30% reduction in operational downtime due to pump-related issues.

**Tips:** Always request case studies or references from previous projects to gauge the specialist's problem-solving capabilities. Furthermore, ensure they are up-to-date with the latest technologies and trends in the pumping industry, as this knowledge can significantly impact the efficiency and success of your projects. Collaboration with specialists who regularly engage in continuous training can lead to better outcomes and innovations in your pumping solutions.

When selecting a pump specialist for your projects, it’s crucial to assess their certifications and adherence to industry standards. Certifications demonstrate a contractor's commitment to quality and safety, with organizations like the Hydraulic Institute (HI) and the American Society of Mechanical Engineers (ASME) providing rigorous guidelines for pump services. According to a report by the Market Research Future, the global industrial pump market size was valued at approximately $52 billion in 2020 and is projected to grow at a CAGR of around 5.5% from 2021 to 2027. This growth underscores the necessity for skilled professionals who not only understand complex systems but can also navigate regulatory compliance effectively.

Additionally, evaluating a pump specialist’s adherence to industry standards can significantly impact the reliability and efficiency of your projects. For instance, compliance with standards set forth by the International Organization for Standardization (ISO) ensures that the services provided meet global benchmarks for quality. A 2021 report by Business Research Company highlights that companies with certified professionals experience a 20% increase in project efficiency compared to those without. This statistic emphasizes the importance of choosing a pump specialist who not only holds recognized certifications but also prioritizes continual training and compliance with evolving industry standards, ensuring you receive the best service tailored to your specific needs.

When selecting a pump specialist, comparing the cost and value of different options is crucial for making an informed decision. Cost is often the first factor that comes to mind; however, it is important to remember that the lowest price does not always equate to the best value. Different pump specialists may offer varying levels of expertise, quality of equipment, and customer service, which can significantly impact the overall performance and longevity of your project. Therefore, a thorough assessment of what each specialist brings to the table is essential.

In evaluating the value provided by a pump specialist, consider their experience and track record in delivering reliable solutions. A specialist with a robust portfolio and positive client feedback is likely to offer greater assurance of quality. Additionally, consider the support services they provide, such as installation, maintenance, and troubleshooting. This support can save you time and money in the long run by ensuring that any issues are promptly addressed. Ultimately, while cost is an important factor to weigh, the overall value derived from a pump specialist’s expertise, reliability, and service will influence the success of your projects significantly.

When selecting a pump specialist for your needs and projects, checking their references and reviews is essential to assess their quality and reliability. Start by gathering a list of potential specialists and investigate their previous work. Contact former clients directly to inquire about their experiences, addressing aspects such as the quality of work, adherence to timelines, and responsiveness to concerns. Personal testimonials can provide invaluable insight, revealing both strengths and potential red flags that may not be apparent from promotional materials.

Online reviews are another critical component of evaluating a pump specialist. Platforms that feature customer feedback can shed light on the consistency of a specialist's performance. Pay attention to trends in reviews—if multiple clients mention similar issues, it may indicate systemic problems. Look for specialists who maintain high ratings over extended periods, as this often suggests a commitment to service excellence. A comprehensive approach to examining references and reviews will empower you to make a more informed decision, ensuring that you choose a pump specialist who meets your expectations and project requirements.