Sealless Pumps for a Safer and Greener World

In the intricate world of industrial pumping solutions, selecting the right canned motor pump can significantly impact operational efficiency and reliability. According to Dr. Emily Thompson, a renowned expert in fluid dynamics, “The choice of a canned motor pump is crucial for maintaining the integrity of the fluid system, especially in environments where leakage is a concern.” This insight underscores the importance of thorough consideration when choosing a canned motor pump for specific applications.

As industries evolve and the demand for more efficient and safe pumping solutions increases, understanding the key factors in selecting a canned motor pump becomes essential. From analyzing the specific needs of your system to evaluating the various designs and materials available, making the right choice can mean the difference between a seamless operational flow and costly downtimes. This article presents the top 10 tips for choosing the right canned motor pump tailored to your unique requirements, ensuring that you make an informed decision for your pumping needs.

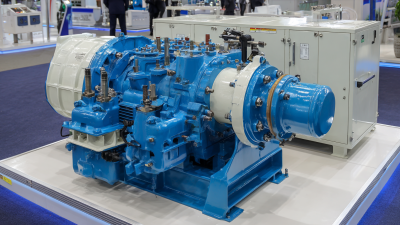

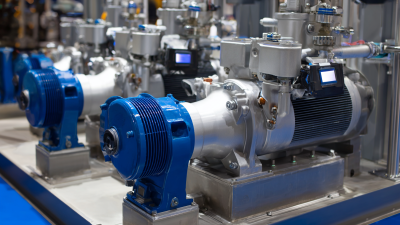

Canned motor pumps are specialized devices designed to ensure the safe and efficient transfer of fluids in a variety of applications. Their construction features a motor that is enclosed within a canister, preventing fluid leakage and contamination. This design is particularly advantageous in environments where maintaining cleanliness and preventing spills are critical, such as in chemical processing or food and beverage production. Understanding these basic concepts is essential when considering the integration of canned motor pumps into your operations.

When selecting a canned motor pump, it’s crucial to assess the specific requirements of your application. One key tip is to evaluate the fluid characteristics, including viscosity, temperature, and corrosiveness. This will help ensure that the pump's materials and design can withstand the operational demands. Additionally, consider the system's flow rate and head requirements to select a pump that meets your performance needs. Another important aspect is the energy efficiency of the pump; opting for models that provide a higher efficiency can lead to significant cost savings over time.

Lastly, always prioritize the reliability and maintenance of the canned motor pump. Look for features such as easy access for servicing and the availability of spare parts, which can greatly reduce downtime. By keeping these tips in mind, you can confidently choose a canned motor pump that aligns perfectly with your operational needs.

When selecting a canned motor pump, several key factors should be carefully considered to ensure optimal performance for your specific application. First, it is crucial to assess the type of fluid being pumped. Different fluids possess varying characteristics such as viscosity, temperature, and chemical reactivity, which can greatly influence pump selection. Ensure that the materials used in the pump construction can effectively handle the properties of the fluid to avoid corrosion or material failure.

Another important aspect is the operating conditions under which the pump will function. Factors like required flow rate, discharge pressure, and ambient temperature must be taken into account. Additionally, understanding the installation environment is essential. Consider whether the pump will be subject to vibration, pressure fluctuations, or other operational stresses. Pump efficiency and energy consumption should also be examined; a more efficient pump can yield significant savings in energy costs over time. By prioritizing these factors, you can choose a canned motor pump that best meets your operational needs while ensuring reliability and longevity.

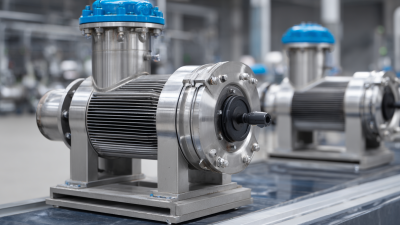

When selecting a canned motor pump, evaluating the performance specifications is crucial to ensure it meets the unique requirements of your application. Start by analyzing the flow rate and head pressure needed for your processes. Understanding the fluid's viscosity and density is also important, as these properties significantly affect the pump's efficiency and effectiveness. Opt for a pump that provides a suitable performance curve, allowing you to visualize how it will operate under different conditions and to ascertain compatibility with your system.

Additionally, consider the specific environment in which the pump will be operating. Factors such as temperature range, chemical compatibility, and space constraints can influence the selection process. For example, extreme temperatures may necessitate specialized materials to withstand potential degradation, while corrosive fluids could require a pump built with resistant components. By closely matching the pump's performance specifications to both the operational environment and your system's demands, you can achieve optimal performance, reliability, and longevity for your pumping solution.

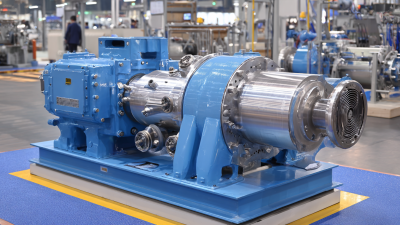

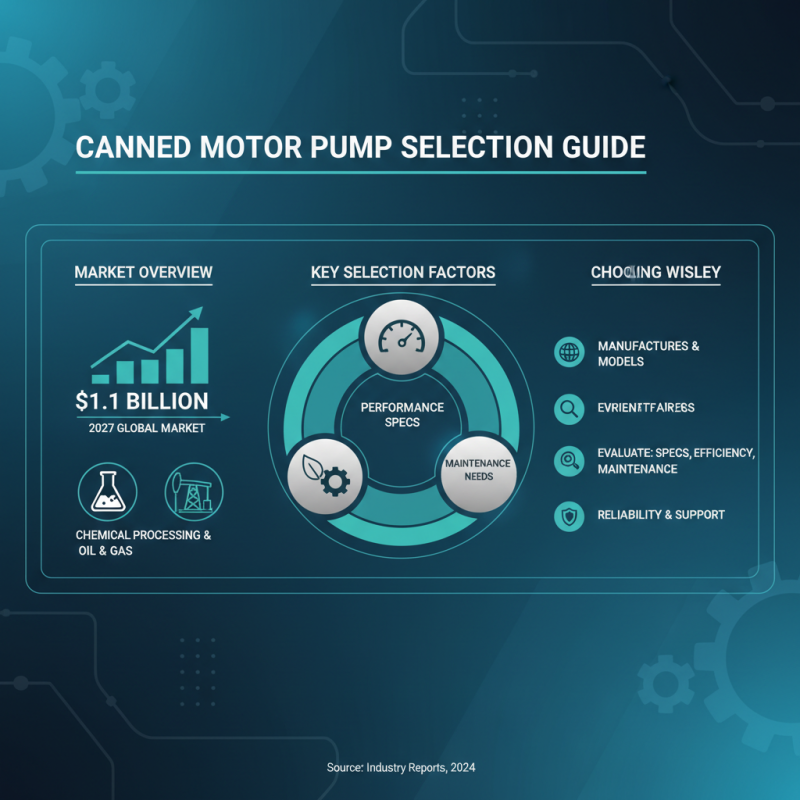

When it comes to selecting the right canned motor pump, understanding the various manufacturers and their specific models is crucial. Industry reports indicate that the global canned motor pump market is anticipated to reach $1.1 billion by 2027, driven largely by increased demand in the chemical processing and oil and gas sectors. With numerous options available, factors such as performance specifications, efficiency, and maintenance needs should be evaluated closely.

Different manufacturers may offer varying technologies and configurations that can impact the overall efficiency and reliability of the pump. For example, some models may feature advanced impeller designs that can improve hydraulic performance, while others might prioritize robustness in challenging environments. Analyzing performance data, including flow rates and energy consumption metrics, can be instrumental in comparing models. Furthermore, understanding warranty and service agreements play an essential role in long-term operational costs and reliability. As with any critical industrial equipment, thorough research and comparison of manufacturers' specifications, alongside insights from experts in the field, can significantly inform the decision-making process.

When it comes to maintaining your canned motor pump, regular checks and scheduled service are essential for ensuring its longevity. One of the primary aspects to focus on is the sealing integrity of the motor. Over time, seals can wear down, leading to leaks and reduced efficiency. Regularly inspecting these seals and replacing them as necessary can prevent more significant issues from developing. Additionally, monitoring the temperature and vibration levels during operation can help in identifying potential problems early.

Proper lubrication is also crucial to maintain optimal functionality. Ensure that the motor components are adequately lubricated according to the manufacturer’s guidelines. Inadequate lubrication can lead to increased friction and wear, eventually leading to failure. Furthermore, keep an eye on the pump’s flow rate and pressure. Sudden changes can indicate underlying issues that could affect both performance and longevity. By implementing these maintenance practices, you can extend the life of your canned motor pump and ensure it operates efficiently for years to come.

| Tip Number | Tip Description | Expected Longevity (Years) | Maintenance Frequency |

|---|---|---|---|

| 1 | Choose the right pump material based on application and fluid type | 10-20 | Annual |

| 2 | Check the pump's operational efficiency for energy savings | 8-15 | Semi-Annual |

| 3 | Ensure compatibility with existing systems and components | 10-15 | Annual |

| 4 | Select a reputable manufacturer with good customer service | 15-25 | Annual |

| 5 | Consider the pump's size and space requirements | 10-20 | Quarterly |

| 6 | Evaluate the noise level of the pump | 10-15 | Annual |

| 7 | Check for availability of spare parts | 15-30 | As Needed |

| 8 | Assess the warranty and service agreement | 5-10 | Annual |

| 9 | Review the maximum and minimum operating conditions | 10-20 | Monthly |

| 10 | Compare the total cost of ownership, not just the purchase price | 10-20 | Annual |