Sealless Pumps for a Safer and Greener World

In the ever-evolving landscape of industrial projects, the selection of appropriate equipment is paramount for ensuring efficiency and reliability. Among the critical components in various applications, API pumps play a significant role in transferring fluids safely and effectively. According to a report by the American Petroleum Institute, the demand for API pumps in sectors such as oil and gas is projected to grow by over 5% annually, emphasizing the necessity for engineers and project managers to understand the selection criteria.

Choosing the right API pumps involves assessing factors such as flow rate, pressure requirements, and the specific characteristics of the fluid being handled. Industry experts suggest that improper selection can lead to operational inefficiencies and increased maintenance costs, which can amount to thousands of dollars over time. An analysis by the Hydraulic Institute indicates that improper pump selection contributes to up to 90% of pump failures, highlighting the importance of adhering to best practices when choosing API pumps for any project. As industries demand higher performance and sustainability, understanding these selection criteria becomes increasingly crucial.

API pumps play a crucial role in various industrial applications, with different types designed to meet specific project requirements. Understanding the classifications and their applications can significantly influence operational efficiency and cost-effectiveness. Common types of API pumps include centrifugal pumps, positive displacement pumps, and screw pumps. According to the API 610 standard, centrifugal pumps are the most widely used due to their versatility in handling a range of fluid viscosities and flow rates. They are particularly favored in the oil and gas industry, accounting for nearly 70% of all rotating equipment used in refineries.

On the other hand, positive displacement pumps, including gear, diaphragm, and piston pumps, are ideal for applications requiring high pressure and precise flow rates. A research report by Frost & Sullivan indicates that the global market for positive displacement pumps is projected to grow at a CAGR of 4.2% from 2021 to 2028, mainly driven by the demand for enhanced fluid management in chemical processing. Meanwhile, screw pumps are recognized for their capability to handle viscous fluids with low shear, making them suitable for applications in food and pharmaceutical industries. Thus, choosing the right API pump requires a thorough understanding of these types and their specific operational contexts to optimize project outcomes.

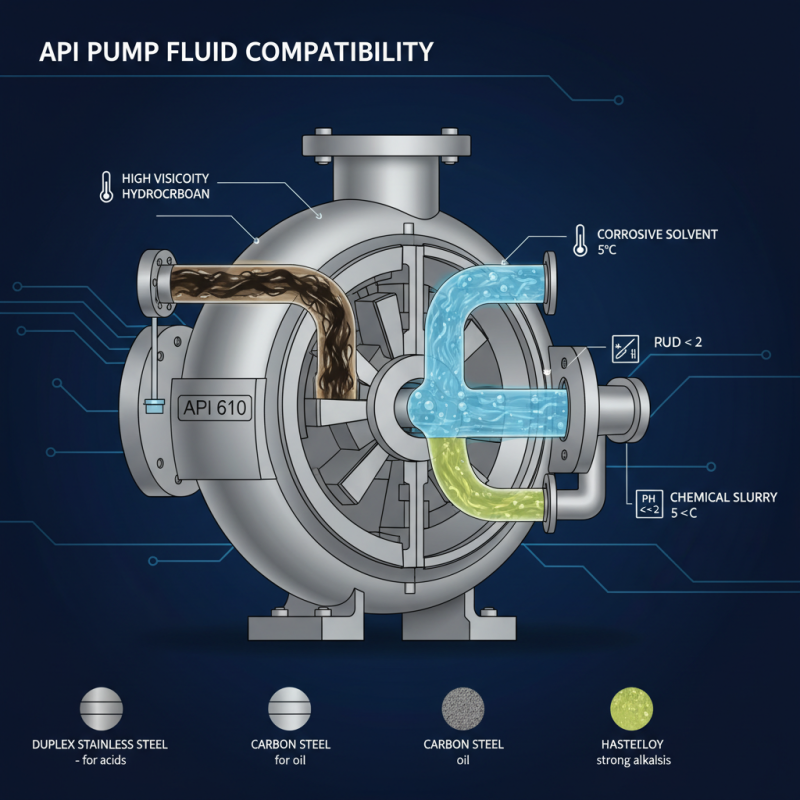

When selecting API pumps for your project, there are several key considerations to keep in mind to ensure you make the right choice for your specific requirements. First, it's essential to understand the characteristics of the fluid you will be pumping. Different fluids have varying viscosities, temperatures, and chemical compositions, which can significantly affect the performance and longevity of the pump. Conduct thorough research on the fluid properties and ensure the pump materials are compatible with them.

Tips: When evaluating pump materials, consider resistance to corrosion and wear, as these factors will directly influence maintenance needs and operational efficiency. Additionally, take into account the flow rate and pressure requirements of your application. Ensuring that the pump can handle the required flow rate without causing strain is critical for maintaining system integrity.

Another important aspect to consider is the pump's operating environment. Factors like space constraints, ambient temperature, and proximity to hazardous materials can impact both the selection and installation process. Be sure to assess the layout of your project site carefully and choose a pump designed for the specific environmental conditions it will face.

Tips: Collaborating with engineers during the planning stage can help identify potential challenges and prevent costly adjustments later on. Additionally, understanding the total cost of ownership, including power consumption and maintenance, can aid in selecting the most efficient model for your project needs.

When selecting API pumps for your project, assessing flow rate and pressure requirements is crucial. The flow rate, measured in gallons per minute (GPM) or liters per minute (LPM), indicates the volume of fluid the pump can move within a certain timeframe. Understanding the specific flow demand of your system ensures that the pump operates efficiently, avoiding scenarios where the pump is oversized or undersized. A pump that is too large can lead to energy inefficiencies, while one that is too small may not meet the operational needs, resulting in delays or equipment strain.

Pressure requirements also play a significant role in the selection process. The total dynamic head (TDH) measurement helps determine how much pressure is necessary to overcome resistance within the system, including elevation changes and friction losses. Each application has unique pressure needs based on the fluid's characteristics and the system's configuration. It is essential to match the pump's pressure capabilities with the calculated TDH to ensure optimal performance and reliability. By carefully evaluating both flow and pressure requirements, you can select the most suitable API pump for your operational needs, leading to a successful and efficient project outcome.

When selecting API pumps for a project, understanding material compatibility and environmental factors is crucial to ensure optimal performance and longevity. The materials used in the construction of the pump must be suited to the fluids they will handle. For instance, corrosive fluids may require pumps made from materials like stainless steel or specially coated alloys to prevent degradation.

Additionally, the temperature and pressure conditions of the application can influence material choices; higher temperatures may necessitate heat-resistant materials, while varying pressures could require a strengthened design to withstand potential stresses.

Environmental factors also play a significant role in API pump selection. Consider the operating environment's exposure to elements such as humidity, dust, or chemicals, which may affect the pump's reliability. For outdoor installations, pumps may need protective features or enclosures to fend off environmental damage. Furthermore, the potential for spills or leaks must be addressed by selecting a pump with designs that minimize risks and are compliant with environmental regulations. Understanding these factors can lead to better decisions that enhance both the safety and efficiency of the pumping system.

When selecting API pumps for a project, evaluating their cost-effectiveness and maintenance needs is crucial for ensuring long-term operational efficiency. Cost-effectiveness involves analyzing upfront acquisition costs, as well as potential long-term savings generated through energy efficiency and reduced operational downtime. A thorough comparison of different pump models, including their performance ratings and anticipated service life, will help project managers make informed financial decisions. Understanding the total cost of ownership, which includes installation, operation, and eventual replacement, is essential for ensuring the selected pumps align with budgetary constraints.

Maintenance needs are equally important in the selection process. Regular maintenance requirements can significantly impact overall project costs and operational continuity. API pumps with simpler designs may offer easier access for routine inspections and repairs, reducing labor costs and downtime. On the other hand, pumps that necessitate specialized tools or experienced technicians for maintenance can lead to increased expenditures. It’s also vital to consider the availability of spare parts and service providers, as these factors can influence both the responsiveness of maintenance services and the overall reliability of the pumping system. By carefully assessing both cost-effectiveness and maintenance demands, project leaders can ensure their selected API pumps will contribute positively to their project objectives.