Sealless Pumps for a Safer and Greener World

Choosing the right marine pumps can be a daunting task. Experts like Captain John Miller emphasize this complexity. He once said, “Selecting the right pump is crucial for smooth sailing.” Understanding your specific needs is vital.

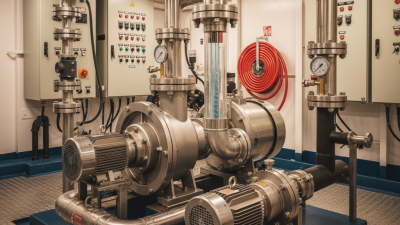

Different marine pumps serve various purposes, from bilge pumps to fuel transfer pumps. Each type has unique specifications and features. For instance, a bilge pump should be reliable in emergencies. Buyers must evaluate their vessel’s size, usage, and the environment.

While many overlook maintenance, it's essential for longevity. Neglecting this can lead to performance issues. Additionally, not all pumps suit every situation. It’s easy to overspend on features you may not need. Consider this carefully when making a decision.

When selecting marine pumps, understanding their types and functions is crucial. There are various pumps for different tasks. Bilge pumps are essential for removing water from the boat’s interior. They help maintain safety and stability. A diaphragm pump is ideal for transferring liquids, particularly those that contain solids. However, it can struggle with high-viscosity fluids.

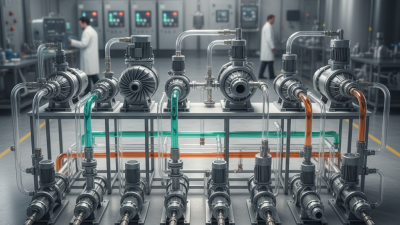

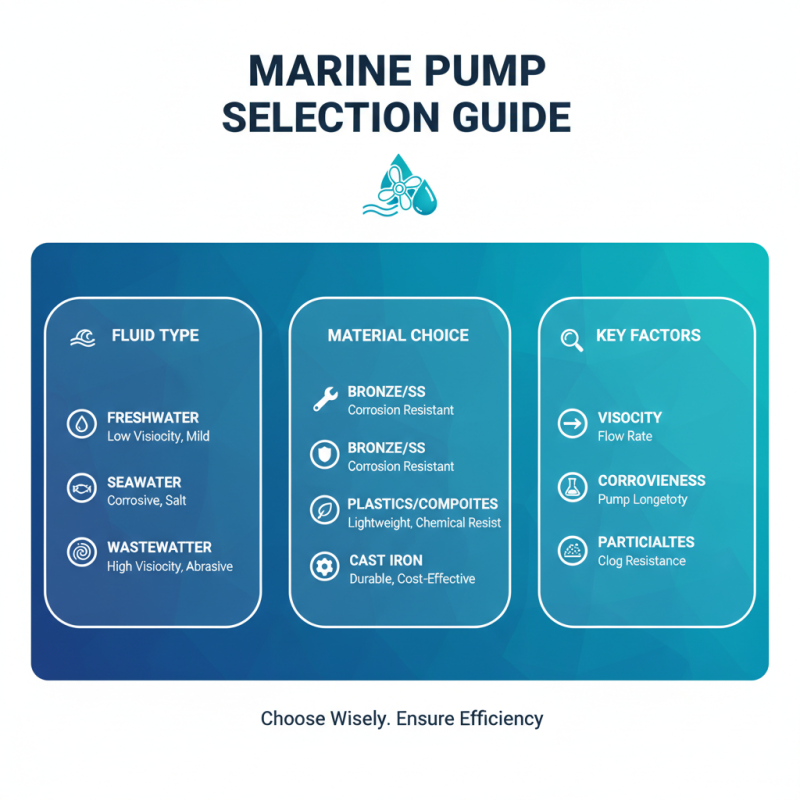

Consider water pumps next. They are typically used for cooling and circulation in engines. Some use centrifugal force while others rely on positive displacement. Knowing the fluid you’ll be handling is key. Some pumps perform poorly with specific liquids. For instance, a pump meant for freshwater can corrode quickly if exposed to saltwater.

Another aspect to assess is the power source. Many pumps run on electricity, while others utilize mechanical systems. Size and flow rate also play a role in functionality. An overpowered pump can lead to splashes and leaks. Conversely, an underpowered pump might not fulfill your needs. Careful evaluation is necessary to avoid costly mistakes in choosing the right marine pump.

Choosing the right marine pumps requires careful consideration of various factors. Think about the type of fluid you'll be moving. Freshwater, seawater, or wastewater all demand different pump designs. Each substance has its own viscosity and corrosiveness. These attributes affect the choice of materials in the pump construction.

Pay attention to the flow rate needed for your application. Calculate the required gallons per minute (GPM). A pump too powerful may waste energy. On the other hand, a pump that is too weak can lead to inefficiency. If you are moving water from a bilge, for example, you'll need a pump that can handle sudden bursts of flow.

Tips: Always consider the power source for your pump. Electric pumps are great for quieter operations. However, if you're far from a power source, a manual or fuel-operated pump might be necessary. Don't forget to inspect the installation space. It is important that the pump fits well and allows for maintenance. Experience shows that poor installation can lead to frustrating leaks and operational problems.

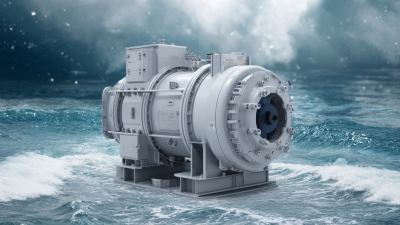

Choosing the right marine pumps can be daunting. Performance and efficiency are crucial. According to the International Marine Organization, over 50% of energy consumption in marine operations comes from pumping systems. Selecting the right pump can significantly reduce this energy use.

Efficiency ratings matter. Look for pumps with high-performance curves. The hydraulic efficiency of a well-designed pump can reach 85%. However, many pumps underperform. A study showed that nearly 30% of marine pumps operate below their optimal efficiency. This is often due to improper sizing or selection.

Maintenance practices also influence performance. Regular inspections can help identify wear and tear early. A report from the Marine Engineering Society indicates that 40% of pump failures result from inadequate maintenance. Improving monitoring techniques can save time and costs in the long run. Reflecting on these factors is essential for making informed choices.

When considering marine pumps, maintenance is crucial for longevity. Regular checks can prevent costly breakdowns. Studies show that 30% of marine pump failures result from inadequate maintenance. Simple tasks, like checking seals and impellers, make a significant difference. Ignoring these small details leads to bigger problems down the line.

The lifespan of a marine pump can reach beyond 10 years with proper care. Yet, many operators fail to perform routine inspections. A recent report noted that 25% of marine pumps did not meet expected performance levels due to poor upkeep. This highlights a critical gap in maintenance practices. Investing time in maintenance can yield substantial savings.

Operators should keep detailed logs of pump performance. This data can reveal patterns that indicate when service is necessary. After all, proactive maintenance outperforms reactive strategies. Reflecting on past experiences can guide future decisions. Without a consistent approach to upkeep, the risk of unexpected failures rises sharply.

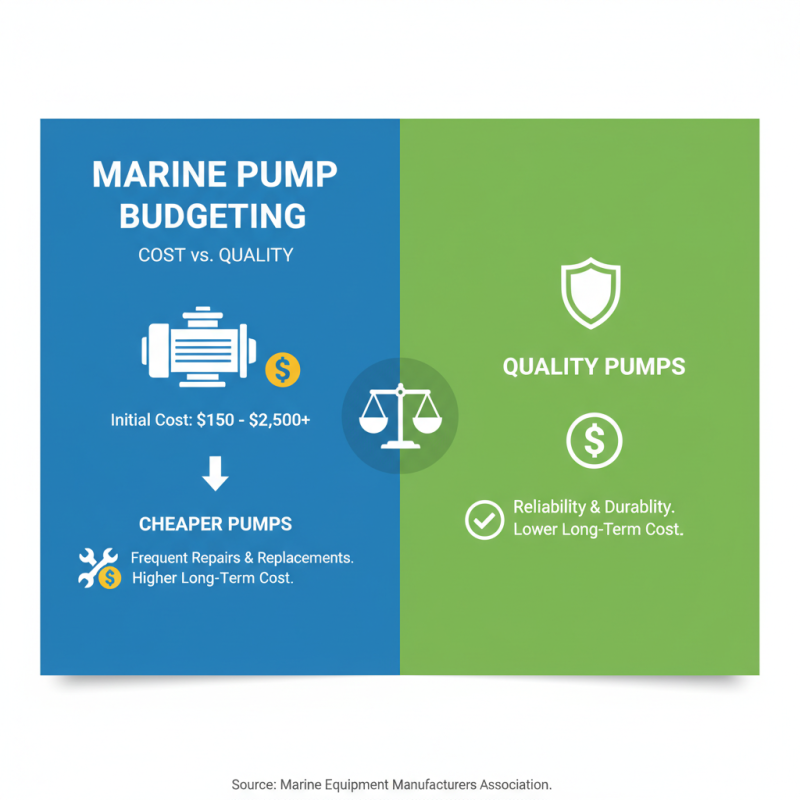

Budgeting for marine pumps requires a careful balancing act between cost and quality. According to the Marine Equipment Manufacturers Association, reliable marine pumps can range from $150 to over $2,500 based on types and specifications. Opting for cheaper options may seem wise initially, yet the long-term costs of repairs and replacements can outweigh any short-term savings.

Quality should not be compromised. Studies reveal that high-quality pumps often last up to 50% longer than their lower-cost counterparts. A poor choice could lead to frequent failures. Frequent replacements can disrupt operations and add unexpected expenses. Furthermore, according to a report by the International Maritime Organization, maintenance costs can account for up to 20% of total operating expenses for vessel owners.

Investing in durable pumps may require a larger upfront budget. However, it also mitigates hidden costs over time. It’s essential to evaluate how much downtime is worth during peak seasons. Would a cheaper pump lead to delays and loss of revenue? Reflect on the balance between price and reliability. Quality marine pumps can serve well and minimize operational hiccups.