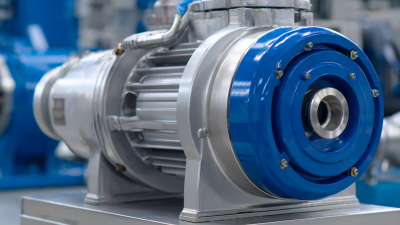

Sealless Pumps for a Safer and Greener World

When it comes to selecting the appropriate pump for industrial applications, one must navigate a myriad of factors that can significantly affect performance and reliability. Among the various standards available, API 685 pumps stand out due to their specific design features tailored for the oil and gas, chemical, and petrochemical industries. These pumps are recognized for their robust construction, ensuring safety and efficiency in handling hazardous fluids. Choosing the right API 685 pump requires a thorough understanding of both operational requirements and the technical specifications of these pumps.

In this guide, we will explore essential tips to consider when selecting API 685 pumps for your industrial needs. We will discuss critical aspects such as flow rate, efficiency, maintenance, and compatibility with various fluids. Understanding these factors will empower you to make informed decisions that enhance operational efficiency and reduce downtime. By the end of this article, you will be well-equipped to select the ideal API 685 pump that meets your industrial demands while ensuring compliance with industry standards.

When selecting the right API 685 pumps for industrial applications, it is essential to understand the fundamentals of pump design and the associated standards. API 685, a standard developed by the American Petroleum Institute, outlines the requirements for sealless centrifugal pumps, emphasizing reliability and safety in the handling of hazardous fluids. This standard covers various aspects of pump design, including materials, mechanical integrity, and performance specifications tailored for the unique demands of the oil and gas sector.

Understanding the API 685 pump standards involves recognizing critical elements such as hydraulic performance, pump construction materials, and the importance of a robust sealing system. The design principles outlined in the standard promote efficient operation while minimizing the risk of leaks, thereby enhancing environmental safety. Additionally, factors like the pump’s NPSH (Net Positive Suction Head) requirements, vibration criteria, and allowable operating ranges must be considered to ensure optimal performance in specific applications. By adhering to these design fundamentals and standards, industries can effectively select pumps that not only fulfill their operational needs but also align with best practices for safety and sustainability.

When selecting API 685 pumps for industrial applications, several key factors must be considered to ensure optimal performance and reliability. One of the most critical aspects is the fluid being handled. According to the Hydraulic Institute's

"Pump Industry Market Research" report, the chemical composition, viscosity, and temperature of the fluid can significantly influence pump selection.

For example, corrosive and viscous fluids often require specific materials and designs to avoid maintenance issues and prolong service life.

Additionally, the API 685 standard emphasizes the need for robust mechanical seals and containment systems to prevent leakage,

which is paramount in processes involving hazardous substances.

Another essential factor is the operating environment of the pump. The American Petroleum Institute (API) provides guidelines for environmental conditions,

including temperature ranges and exposure to chemicals. Reports from the API indicate that pumps operating in extreme conditions may need enhanced features

such as cooling jackets or special coatings to resist wear and degradation.

Finally, the proper sizing of the pump is crucial to maintaining efficiency and achieving the desired flow rates. The Hydraulic Institute states

that improper sizing can lead to operational inefficiencies, increased energy consumption, and accelerated wear, ultimately impacting the overall

cost-effectiveness of the pumping system.

When selecting the right API 685 pumps for industrial applications, comparing performance and efficiency across prominent brands becomes paramount. According to a recent report by the Hydraulic Institute, the efficiency of API 685 pumps can vary significantly depending on the manufacturer. For instance, leading brands such as Sulzer and KSB have shown efficiencies exceeding 85% under optimal conditions, which not only reduces energy consumption but also lowers operational costs. In contrast, some lesser-known brands may only achieve efficiencies around 70%, marking a crucial difference for operators who prioritize cost-saving and sustainability in their processes.

Moreover, the reliability and maintenance frequency of API 685 pumps is a key performance indicator that impacts long-term operational efficiency. A study published in the Journal of Petroleum Technology illustrated that pumps from established manufacturers typically reported an average Mean Time Between Failures (MTBF) of over 20,000 hours, while less reputable options averaged around 10,000 hours. This disparity in reliability not only affects maintenance schedules but can also influence production continuity, emphasizing the importance of selecting pumps that offer both high performance and durable design.

Maintaining the longevity and reliability of API 685 pumps is crucial for industrial operations, especially in hazardous environments. According to the Hydraulic Institute's 2021 report, improper maintenance can decrease pump efficiency by up to 20%, leading to increased operational costs and potential system failures. Regular maintenance practices, such as vibration analysis and thermal imaging, can help identify issues before they escalate. Implementing a structured maintenance schedule that adheres to the manufacturer's recommendations can extend the lifespan of these pumps and ensure they operate at peak performance.

Reliability is also significantly impacted by the quality of components used in API 685 pumps. A study by the American Society of Mechanical Engineers (ASME) found that using high-quality materials can enhance pump reliability by as much as 30%. Upgrading seals and bearings to those specifically designed for handling volatile fluids not only improves the pumps’ performance but also minimizes downtime associated with repairs. Ultimately, investing in quality components and regular maintenance not only secures the pumps’ operational reliability but also contributes to the overall efficiency of industrial systems.

When considering the investment in API 685 pumps for industrial applications, organizations must perform a thorough cost-benefit analysis to ensure they are making wise financial decisions. The global centrifugal pump market is projected to grow significantly, with valuations increasing from $42.20 billion in 2024 to an expected $69 billion by 2030. This robust growth signals a rapidly evolving landscape wherein businesses must carefully assess their pumping solutions to stay competitive.

Investing in high-quality API 685 pumps can lead to significant long-term benefits, particularly in terms of energy efficiency and operational reliability. For instance, efficient pump systems can drastically cut energy costs, aligning with companies' sustainability goals while enhancing productivity. With firms like Arcadia securing $50 million in growth financing to expand their utility data platforms, the emphasis on optimizing resource use and reducing waste has never been more critical. Organizations that strategically invest in advanced pumping solutions will not only see a return on their investment but also help secure their operational future in a challenging economic climate.