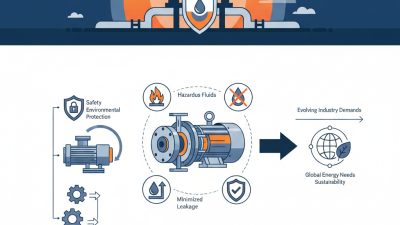

Sealless Pumps for a Safer and Greener World

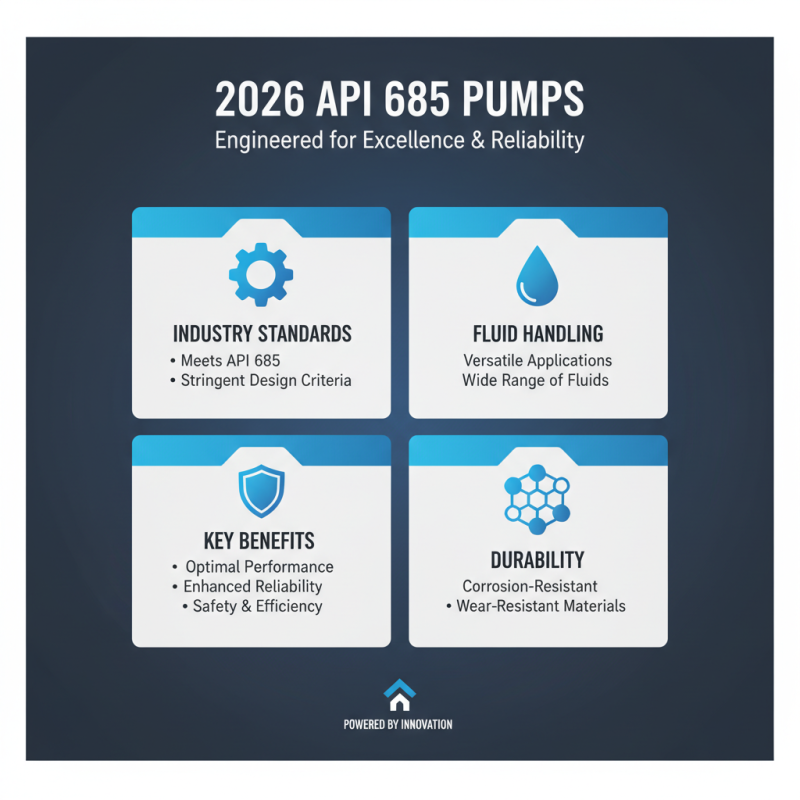

In the world of industrial pumps, API 685 pumps stand out for their reliability. These pumps are vital in many processes. Choosing the right pump can impact efficiency and operational costs. The 2026 best API 685 pumps are designed to ensure optimal performance in challenging conditions.

When selecting API 685 pumps, it's essential to consider factors like material compatibility and design options. Many users overlook these details, leading to poor performance. A well-chosen pump not only reduces downtime but also increases productivity. However, the market is flooded with options, making the decision process daunting.

Each pump has strengths and weaknesses. Some may excel in certain environments while failing in others. It's crucial to reflect on the specific needs of your operation. Investing time in research can help avoid costly mistakes and improve overall success. The right API 685 pump can transform your operations, ensuring reliability and performance for years to come.

The 2026 API 685 pumps are designed to meet stringent industry standards. These pumps are vital for handling a range of fluids in various applications. They focus on reliability and optimal performance. The pumps adhere to specific design criteria, ensuring safety and efficiency in operation. Materials used in these pumps can resist corrosion and wear.

API 685 specifies requirements for centrifugal pumps, especially for the oil and gas sector. One key aspect is the mechanical seal design. It aims for lower leakage rates and extended service life. However, not all pumps meet these standards consistently. Some pumps may struggle with high-pressure applications. This raises concerns about performance in demanding environments.

Other critical specifications include vibration limits and temperature ranges. Failure to meet these can lead to severe operational issues. Users must consider maintenance practices carefully. Regular checks can prevent unexpected failures. Investing in training for personnel is important. It can improve operational efficiency and safety across the board.

When selecting API 685 pumps, several key factors influence their performance and reliability. The design and materials of the pump play a critical role. Pumps constructed from high-quality alloys tend to resist corrosion better. According to a recent industry report, pumps made with duplex stainless steel can last up to 30% longer than those using standard materials.

Operating conditions also greatly impact pump efficiency. High temperatures and pressures require specialized designs to prevent failure. A study highlighted that improper seals could lead to a failure rate increase of 15%. Inadequate attention during maintenance can exacerbate wear and tear, leading to costly breakdowns.

**Tips:** Always examine the pump’s maintenance schedule. Frequent checks can help catch issues early. Additionally, consider the installation environment. Even minor changes in temperature or pressure can affect performance.

The selection of a suitable seal is often overlooked. Seals should match the chemical properties of the fluids they handle. An inappropriate choice can lead to leaks and increased downtime. Remember, choosing the right pump is more than just picking a model. It's about understanding how each component interacts within the system.

The market for API 685 pumps is evolving rapidly. Top manufacturers are innovating to improve performance and reliability. They invest in advanced materials and designs. These changes help meet the demands of various industries. Enhanced durability is a crucial focus. Manufacturers are exploring new technologies, but not all succeed.

Some companies lead in market share, yet competition is fierce. Smaller brands are emerging. They offer unique features and competitive pricing. Consumer feedback is vital for innovation. It drives improvements, yet some manufacturers overlook it. This can lead to gaps in product quality.

Sustainability is another important trend. Several brands are working on eco-friendly solutions. They aim to reduce energy consumption and emissions. However, not every approach is effective. Continuous testing and improvement are necessary. The balance between performance and environmental impact remains a challenge for many.

API 685 pumps are known for their reliability in challenging environments. A case study from the oil and gas sector illustrates this well. A facility faced severe wear in traditional pumps. They switched to API 685 pumps, which handled aggressive fluids with ease. This change reduced maintenance costs significantly. Operators noted fewer breakdowns. However, the installation process was complicated and required skilled labor.

In the chemical manufacturing industry, another example showcases API 685 pumps shining in high-temperature applications. A plant struggled with frequent failures under heat stress. After implementing these pumps, they achieved enhanced efficiency. The operational lifespan increased considerably. Yet, initial performance issues prompted ongoing adjustments. Feedback from operators was crucial for fine-tuning.

Despite these successes, challenges remain. Some users reported difficulties in locating replacement parts. Others faced training gaps for staff. Addressing such issues may improve future applications. API 685 pumps demonstrate great potential but are not without their complexities. Each application requires careful consideration and adaptation.

The future of API 685 pump design is heading towards increased efficiency and reliability. Innovations are shaping the industry, prioritizing energy-saving technologies. Manufacturers are exploring advanced materials that enhance durability. These changes will likely

reduce downtime and maintenance costs.

Digital integration is becoming vital. Smart sensors can monitor pump performance in real-time. This data helps identify potential issues before they escalate. Improved analytics can lead to better predictive maintenance strategies. However, the challenge lies in integrating these technologies seamlessly.

Another trend is the push for sustainability. Pumps are being designed with lower environmental impact in mind. Recycling and energy-efficient systems are essential. The industry must also address the concerns of compatibility with existing infrastructure. Balancing innovation with practicality may require more reflection. It’s crucial to ensure that advancements do not compromise reliability.