Sealless Pumps for a Safer and Greener World

Vertical centrifugal pumps have emerged as a vital component in various industrial applications, thanks to their unique design and operational advantages. These pumps are specifically designed to move fluids vertically, making them ideal for applications that require high efficiency and reliability in fluid transport. Their ability to handle large volumes of fluid while maintaining a compact footprint is one of the primary reasons why vertical centrifugal pumps are favored in industries such as municipal water supply, wastewater management, and industrial processes.

In addition to their efficient fluid handling capabilities, vertical centrifugal pumps are known for their durability and cost-effectiveness. They can be easily integrated into existing systems, and their maintenance is typically straightforward, leading to reduced downtime and operational costs. As industries continue to seek innovative solutions to enhance productivity and sustainability, understanding the benefits of using vertical centrifugal pumps becomes increasingly important. This article will explore the top benefits of these pumps across different applications, highlighting why they are an essential choice for engineers and operators seeking reliable fluid management solutions.

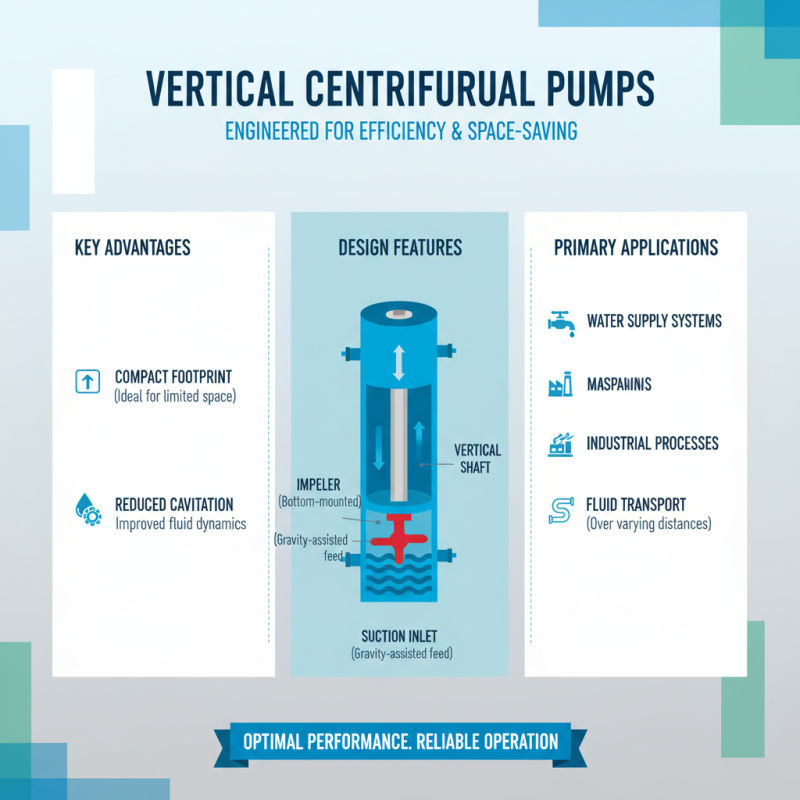

Vertical centrifugal pumps are engineered with a distinct design that allows them to efficiently handle a wide range of applications, from water supply systems to industrial processes. Their vertical configuration provides several advantages, including a compact footprint, which is especially beneficial in environments where space is limited. The pump's design typically features an impeller mounted on a shaft that is positioned vertically, allowing gravity to assist in the flow of liquids. This orientation minimizes the risk of cavitation and improves overall performance, making these pumps ideal for transporting fluids over varying distances.

The design features of vertical centrifugal pumps contribute significantly to their efficiency and reliability. The vertical shaft arrangement not only optimizes the liquid flow but also simplifies maintenance, as many components can be accessed easily without dismantling the entire system. Additionally, these pumps often incorporate high-quality materials to withstand corrosion and wear, enhancing their longevity. Their adaptability allows for customization based on specific application needs, making them suitable for both clean water and abrasive slurries. This flexibility in design enables operators to achieve optimal performance across diverse industrial and municipal applications.

Vertical centrifugal pumps are versatile tools widely used in various industrial settings due to their efficiency in handling large volumes of fluids. One of the primary applications is in water and wastewater treatment facilities. These pumps facilitate the movement of water through different stages of treatment, ensuring effective filtration and chemical treatment processes. Their ability to operate at varying flow rates makes them ideal for adapting to changing demands in these environments.

In addition to water treatment, vertical centrifugal pumps find extensive use in chemical processing industries. They are well-suited for transferring corrosive and viscous fluids, which are often encountered in the production of chemicals and pharmaceuticals. The vertical design allows for space-saving installations while maintaining high operational efficiency. Furthermore, their ability to handle solid particles in suspension makes them useful in applications such as slurry transport in mining and mineral processing, contributing to improved productivity and reduced downtime in industrial operations.

Vertical centrifugal pumps play a pivotal role in water treatment processes due to their unique design and functionality. The vertical design allows for a smaller footprint, making them ideal for facilities where space is at a premium. This characteristic not only maximizes available space but also simplifies the installation process. Additionally, vertical centrifugal pumps are capable of handling large volumes of water efficiently, which is crucial in water treatment applications where consistent and reliable flow is necessary for effective filtration and chemical dosing.

Another significant advantage of these pumps in water treatment is their energy efficiency. Vertical centrifugal pumps typically consume less energy compared to their horizontal counterparts, leading to reduced operational costs. Their ability to manage varying flow rates and pressures ensures that they can adapt to the fluctuating demands of water treatment systems. Furthermore, the construction materials used in these pumps are often resistant to corrosion and wear, ensuring longevity and lower maintenance requirements, which are essential in environments where contaminants are present. This reliability makes vertical centrifugal pumps an excellent choice for maintaining the integrity and efficiency of water treatment processes.

This chart illustrates the key advantages of using vertical centrifugal pumps in various water treatment processes, highlighting their energy efficiency, space-saving design, operational versatility, ease of maintenance, and cost-effectiveness.

Vertical centrifugal pumps are renowned for their efficiency and performance, making them a popular choice across various industries. One of the primary advantages of these pumps is their ability to handle large volumes of liquid while maintaining high efficiency. The vertical design minimizes the footprint, allowing for optimal use of space in facilities where installation area is limited. Additionally, these pumps are capable of handling fluids with varying viscosities, making them versatile for applications ranging from water treatment to chemical processing.

The performance benefits of vertical centrifugal pumps extend beyond their design. They typically feature lower maintenance costs due to fewer moving parts compared to traditional horizontal pumps. This not only reduces downtime but also ensures that the pumps operate at peak performance for longer periods. Furthermore, advancements in materials and engineering have led to pumps that can withstand harsh operating conditions, enhancing their reliability and lifespan. Overall, the efficient operation and durability of vertical centrifugal pumps contribute significantly to improved productivity and reduced operational costs, solidifying their place in a spectrum of industrial applications.

When it comes to maintaining vertical centrifugal pumps, a proactive approach is essential to ensure their longevity and optimal performance. Regular inspection and servicing of components such as bearings, impellers, and seals can prevent unexpected failures that may lead to costly downtime. Operators should implement a systematic maintenance schedule that includes checking the lubrication levels, as well as monitoring the alignment and vibration of the pump. These measures help in identifying potential issues before they escalate, thus maintaining the efficiency and reliability of the pumping system.

Moreover, attention should be given to the pump's operating environment. Factors such as temperature, humidity, and exposure to corrosive substances can significantly impact the lifespan of vertical centrifugal pumps. Ensuring that pumps are installed in a suitable environment and are protected against harsh conditions will aid in reducing wear and tear. Additionally, training staff on proper operational techniques and maintenance practices can lead to enhanced performance and decreased maintenance needs over time. In summary, a well-planned maintenance strategy, coupled with environmental considerations, is crucial to maximizing the effectiveness of vertical centrifugal pumps in various applications.

| Application Area | Benefits | Maintenance Considerations |

|---|---|---|

| Water Treatment | Efficient water transfer and energy savings | Regular inspection of seals and bearings |

| Industrial Process | High flow rates and reliability | Lubrication of moving parts and regular system checks |

| Chemical Processing | Corrosion resistance and safety in handling | Ensure compatibility with chemicals and leak detection |

| Irrigation Systems | Uniform distribution of water | Filter cleaning and pump alignment checks |

| HVAC Systems | Energy efficiency and low operational costs | Routine maintenance schedules and vibration analysis |