Sealless Pumps for a Safer and Greener World

In the dynamic world of industrial technology, the efficiency and performance of API pumps play a crucial role in various applications across sectors such as pharmaceuticals, oil and gas, and water treatment. As industry experts emphasize the importance of optimizing these systems, Jonathan Smith, a renowned specialist in fluid dynamics, once stated, "Maximizing the efficiency of API pumps not only enhances operational performance but also significantly reduces long-term costs." This statement underlines the imperative need for businesses to adopt best practices in maintaining and improving their API pump systems.

The ability to improve API pump efficiency directly impacts operational reliability and sustainability. By implementing advanced techniques and strategies, organizations can unlock their full potential and ensure that their systems not only meet but exceed industry standards. In this article, we will explore the top ten tips aimed at optimizing API pumps, focusing on practical solutions that can be integrated into existing operations. As we delve into these strategies, we will highlight crucial insights and methodologies that can drive success in the ever-evolving landscape of API pumping technology.

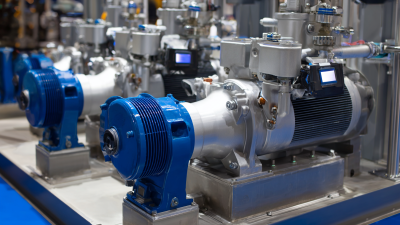

API pumps, or American Petroleum Institute pumps, are essential components in the fluid transport sector, particularly within the oil and gas industry. Understanding key concepts and terminology associated with API pumps is crucial for optimizing their performance. The fundamental purpose of an API pump is to move fluids from one location to another, serving various functions such as transferring crude oil, water, and other liquids. Key terminology includes "flow rate", which refers to the volume of fluid that a pump can transport in a specified time, and "head", denoting the height to which a pump can raise the liquid. These metrics are vital for selecting the appropriate pump for specific applications.

Another important concept is "volumetric efficiency", which measures how effectively a pump converts input energy into fluid movement. API pumps are designed with various configurations, such as centrifugal and positive displacement pumps, each suited for different operational conditions. For instance, centrifugal pumps are commonly used for high-flow applications, while positive displacement pumps are ideal for situations requiring consistent flow at high pressures. Understanding these terms and their implications can significantly impact the efficiency and performance of API pumps, allowing operators to make better-informed decisions regarding their fluid transport systems.

When assessing pump efficiency, it is crucial to consider several key metrics and measurement techniques that can provide insights into performance. One primary metric is the overall efficiency, which is determined by the ratio of hydraulic power output to the mechanical power input. According to the Hydraulic Institute, a well-maintained pump can achieve efficiencies of over 80%, highlighting the significant impact of proper maintenance and operational practices on performance. Additional metrics such as volumetric efficiency and isentropic efficiency also offer valuable perspectives, helping engineers fine-tune their systems for optimal output.

Measurement techniques vary from basic methods such as flow rate and pressure measurements to more sophisticated approaches like using advanced data analytics and performance monitoring systems. The use of flow meters combined with pressure transducers allows for real-time assessment of pump conditions, enabling operators to identify inefficiencies quickly. A report from the American Society of Mechanical Engineers points out that implementing continuous monitoring can lead to a reduction in energy costs by up to 20%, showcasing the financial benefits of efficient pump operations. Emphasizing the significance of these metrics and measurement methods ensures enhanced reliability and performance in pumping systems across various industries.

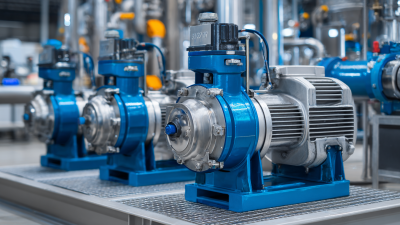

When considering the efficiency and performance of API pumps, several common factors can significantly influence their reliability and effectiveness. Primarily, the design and materials used in pump construction play a crucial role. Pumps must be engineered to withstand the specific fluids they handle, including their viscosity, temperature, and potential corrosiveness. Improper selection or deterioration of materials can lead to leaks or failures over time, impacting overall performance and necessitating costly repairs.

Another critical aspect to examine is the operating environment in which the pump functions. Factors such as ambient temperature, humidity, and even vibration can affect pump performance. Implementing proper installation practices, such as ensuring alignment and minimizing mechanical stress, can enhance reliability. Additionally, regular maintenance routines, including inspection of seals, bearings, and impellers, can help identify early signs of wear and prevent unexpected downtime. By focusing on these factors, operators can optimize pump performance and ensure a longer lifespan, contributing to more efficient operations overall.

Maintaining API pumps for optimal operation involves a series of best practices that can significantly enhance their efficiency and longevity. Firstly, regular inspection of the pump components is crucial. Check for signs of wear and tear, such as leaks, vibration, and unusual noises, which can indicate underlying issues. Ensuring that all connections are secure and that seals are intact can prevent unnecessary downtime and repairs. Additionally, monitoring flow rates and pressure levels can help identify performance deviations early, allowing for timely interventions before more severe problems arise.

Furthermore, it is essential to establish a routine maintenance schedule that includes cleaning and lubrication of moving parts. Proper lubrication reduces friction and wear, ultimately prolonging the pump's operational lifespan. Moreover, using filters or strainers can protect the pump from contaminants that can lead to blockages and damage. Documentation of maintenance activities can also be beneficial, as it provides a historical record that can be useful for troubleshooting and analyzing performance trends over time. By adhering to these practices, operators can ensure that API pumps operate efficiently, delivering reliable performance throughout their service life.

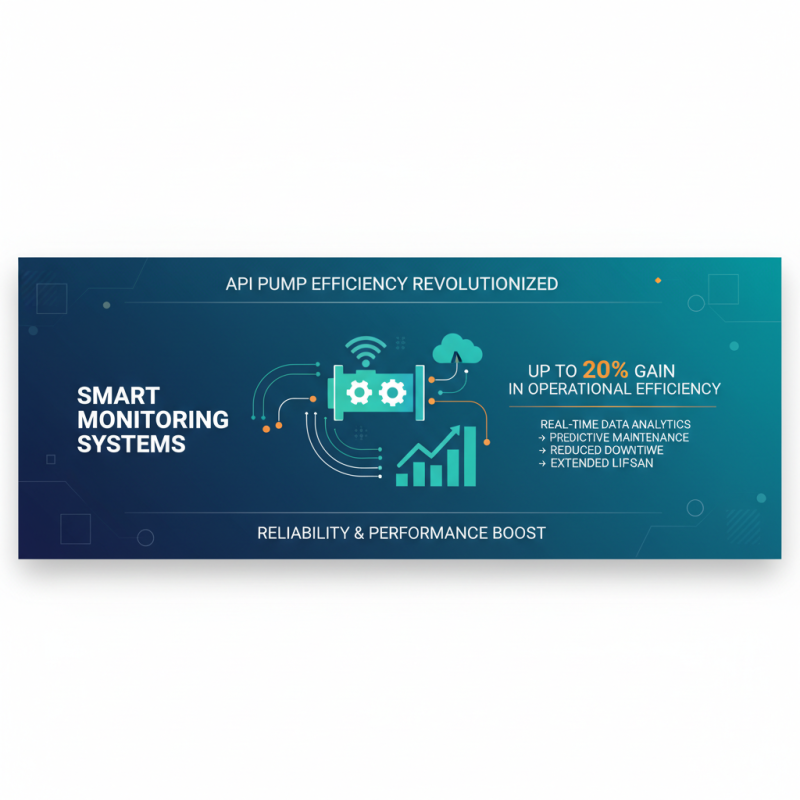

Innovative technologies are revolutionizing API pump efficiency, providing significant improvements in both performance and reliability. According to a report by the Global API Pump Market Analysis, advancements in smart monitoring systems have shown promise in enhancing operational efficiency by up to 20%. These systems utilize real-time data analytics to monitor pump performance, enabling predictive maintenance that reduces downtime and extends equipment lifespan. This proactive approach mitigates the risks associated with unplanned outages, crucial for industries reliant on continuous operation.

Moreover, the integration of variable frequency drives (VFDs) has demonstrated remarkable benefits in energy consumption and overall system performance. A study published by the International Journal of Advanced Manufacturing Technology highlighted that implementing VFDs can result in energy savings of 30% or more compared to traditional constant-speed pumps. By adjusting the pump's speed to match the actual demand, VFDs not only enhance efficiency but also lower operational costs significantly. These innovative technologies are crucial for industries looking to maximize productivity while minimizing environmental impact, underscoring the ongoing evolution within the API pump sector.