Sealless Pumps for a Safer and Greener World

In today's fast-paced industrial landscape, the need for efficient fluid transfer solutions has become more critical than ever. Fluid management is a fundamental component across various sectors, from chemical processing to oil and gas, where precise and reliable transfer systems are essential to operational success. Among the myriad of flow equipment available, API pumps have emerged as a vital tool in achieving these efficiency goals. Engineered to meet rigorous standards, API pumps facilitate the effective movement of liquids, ensuring minimal downtime and optimal performance in challenging environments.

The significance of API pumps transcends mere functionality; their design and operational capabilities are tailored to handle diverse applications while maintaining safety and reliability. By utilizing these pumps, industries can optimize workflows, reduce energy consumption, and enhance the overall performance of their fluid transfer systems. The integration of API pumps into industrial processes not only streamlines operations but also contributes to sustainable practices, as effective fluid movement leads to reduced waste and resource utilization. As industries continue to evolve, understanding the importance of API pumps becomes imperative for stakeholders aiming to remain competitive and efficient in their operations.

API pumps play a crucial role in fluid transfer systems across various modern industries, including oil and gas, pharmaceuticals, and chemical manufacturing. Defined by the American Petroleum Institute, API pumps are designed to handle the rigorous demands of these industries, ensuring safe and efficient movement of fluids. According to a recent report by the Global Fluid Transfer Market Analysis, the demand for efficient fluid transfer solutions is projected to grow by 5.7% annually through 2028. This growth underscores the increasing reliance on API pumps for reliable fluid management.

One significant advantage of API pumps is their ability to accommodate a wide range of viscosities and flow rates, making them indispensable for processes that require precise control. Their design and construction adhere to stringent standards, which minimizes the risk of leaks and enhances operational safety. A study by the Fluid Handling Association emphasizes that using API-compliant systems can reduce maintenance costs by up to 20% due to their longevity and efficiency. With industries facing increasing pressure to optimize production while adhering to regulatory standards, API pumps stand out as a smart investment.

**Tips:** When selecting an API pump for your fluid transfer system, consider the specific viscosities of the fluids you'll be handling. Additionally, regular maintenance checks can prevent potential downtime, ensuring your operations remain uninterrupted and efficient. Always consult industry reports and guidelines to stay informed about the latest advancements and best practices in pump technology.

| Parameter | Value | Unit |

|---|---|---|

| Maximum Flow Rate | 500 | L/min |

| Max Operating Pressure | 150 | bar |

| Efficiency | 85 | % |

| Power Consumption | 5 | kW |

| Fluid Temperature Range | -10 to 100 | °C |

| Weight | 200 | kg |

| Materials of Construction | Stainless Steel | N/A |

API pumps play a crucial role in modern industries, particularly when it comes to the efficient transfer of fluids. These pumps are designed to meet industry standards, ensuring reliable performance in demanding applications. According to a report by the Global Pump Market, the demand for API pumps is expected to grow by 4% annually, driven by their high efficiency and durability, which are essential for minimizing downtime in fluid management operations.

One of the key advantages of using API pumps is their versatility in handling various types of fluids, including corrosive and high-viscosity materials. This adaptability makes them suitable for a wide range of applications, from petroleum to chemical processing. Their robust design not only enhances their lifespan but also decreases maintenance costs, further boosting operational efficiency. Additionally, API pumps often require less energy to operate compared to traditional pump systems, translating to significant cost savings for industries.

Tips:

Ensure regular maintenance checks on API pumps to prolong their lifespan and maintain efficiency. Implementing a monitoring system can help identify potential issues early on, preventing costly repairs. Furthermore, training staff on best practices for fluid management can optimize pump performance and enhance overall productivity in your operations.

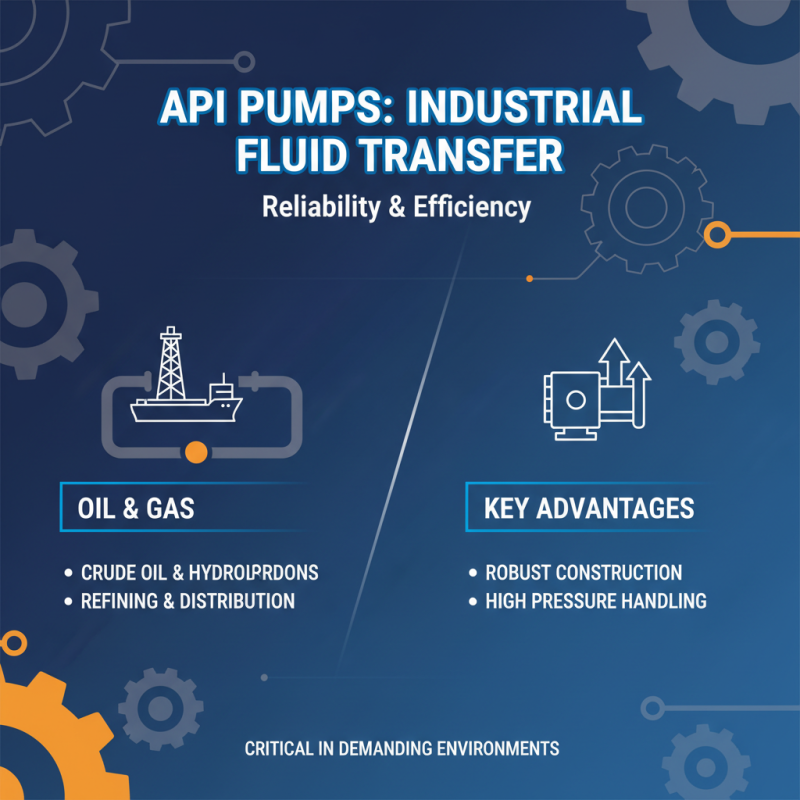

API pumps are pivotal in a range of modern industries due to their reliability and efficiency in fluid transfer. In the oil and gas sector, these pumps are utilized for transporting crude oil and other hydrocarbons, ensuring smooth operation in various applications such as refining and distribution. Their robust construction and ability to handle high pressures make them ideal for the demanding environment typical in this industry.

In the pharmaceutical industry, API pumps excel in transferring liquids with precision, which is crucial for ensuring proper formulations and dosages. The hygiene standards required in this sector dictate the use of pumps that can deliver without contamination, making API pumps a popular choice for not only liquid transfers but also cleaning systems within manufacturing processes.

Tip: Regular maintenance of API pumps can significantly prolong their lifespan and improve efficiency. Ensure that you conduct routine inspections and replace worn components promptly. Additionally, always consult the manufacturer's guidelines for optimal operating conditions to enhance performance and prevent unexpected downtimes.

In the food and beverage industry, these pumps are employed to move various liquids, from oils to sauces, while adhering to strict hygiene regulations. Their ability to handle different viscosities and shear-sensitive fluids without compromising product integrity is a key advantage, making API pumps indispensable in manufacturing and packaging processes.

Tip: When selecting an API pump for food applications, prioritize those made from food-grade materials to comply with health regulations, ensuring safe and clean product transfer throughout your operations.

API pumps have become integral to modern industries, particularly due to their role in enhancing operational efficiency and reliability. According to a report by the Global Market Insights, the demand for centrifugal pumps—which often align with API standards—was valued at over $27 billion in 2020 and is expected to grow significantly by 2027. This growth reflects a broader trend where industries increasingly prioritize fluid services that can deliver high reliability and minimize downtime. API pumps achieve this through standardized designs that ensure compatibility and performance consistency, ensuring that businesses can operate smoothly without interruptions.

In addition to operational efficiency, API pumps are designed to withstand the demanding environments typical in industries such as oil and gas, chemicals, and pharmaceuticals. The American Petroleum Institute (API) has set rigorous standards that these pumps must meet, ensuring durability and safety in fluid transfer operations. Furthermore, a study by the American Society of Mechanical Engineers (ASME) highlights that the use of API pumps can reduce energy consumption by approximately 15-20% compared to other pump types, leading not only to cost savings but also to reduced environmental impact. Such efficiency gains contribute significantly to the overall productivity of industrial processes, showcasing why API pumps are an essential investment for companies aiming to thrive in competitive markets.

The future of API pump technology is poised for transformative advancements, particularly as industries demand greater efficiency and sustainability in fluid transfer solutions. Recent market reports indicate that the global industrial pumps market is projected to reach approximately $60 billion by 2028, reflecting a compound annual growth rate (CAGR) of around 5.8% from 2021 to 2028. This growth underscores the increasing reliance on API pumps in sectors such as oil and gas, water treatment, and chemical manufacturing, driven by their efficiency and ability to handle a wide range of fluid characteristics.

As industries evolve, API pump technology is adapting to meet emerging challenges. The integration of IoT devices into pumping systems enables real-time monitoring and predictive maintenance, reducing downtime and improving operational efficiency. Additionally, advancements in materials science are leading to the development of corrosion-resistant and lightweight pump components, further enhancing the durability and performance of API pumps in demanding environments.

Tips for optimizing API pump performance include regular maintenance checks that focus on seal integrity and alignment, which can significantly reduce leakage risks and prolong pump lifespans. Moreover, investing in training for operators on the latest technologies can foster a deeper understanding of fluid dynamics, enabling better decision-making regarding pump selection and operation in various applications.