Sealless Pumps for a Safer and Greener World

In the ever-evolving landscape of the oil and gas industry, API 685 pumps have emerged as a pivotal component in enhancing operational efficiency and safety. According to John Smith, a renowned expert in fluid dynamics, "API 685 pumps are not just pumps; they are critical lifelines that ensure the integrity of our operations." This statement underscores the significance of API 685 pumps in managing the complex fluids associated with oil and gas extraction and processing.

The unique design and stringent standards of API 685 pumps make them ideal for the challenging conditions encountered in the industry. These pumps are specifically engineered to handle hazardous fluids while minimizing the risk of leakage, thereby protecting both the environment and personnel. As industry demands increase, the role of API 685 pumps becomes more crucial, aligning with the sector's commitment to safety, compliance, and sustainability.

As we delve deeper into the necessity of API 685 pumps, it becomes clear that their attributes not only facilitate operational efficiency but also support the industry's overarching goal of meeting global energy needs responsibly. In a world where reliability is paramount, API 685 pumps stand out as essential assets in the oil and gas sector, ensuring seamless operations while safeguarding the future of energy production.

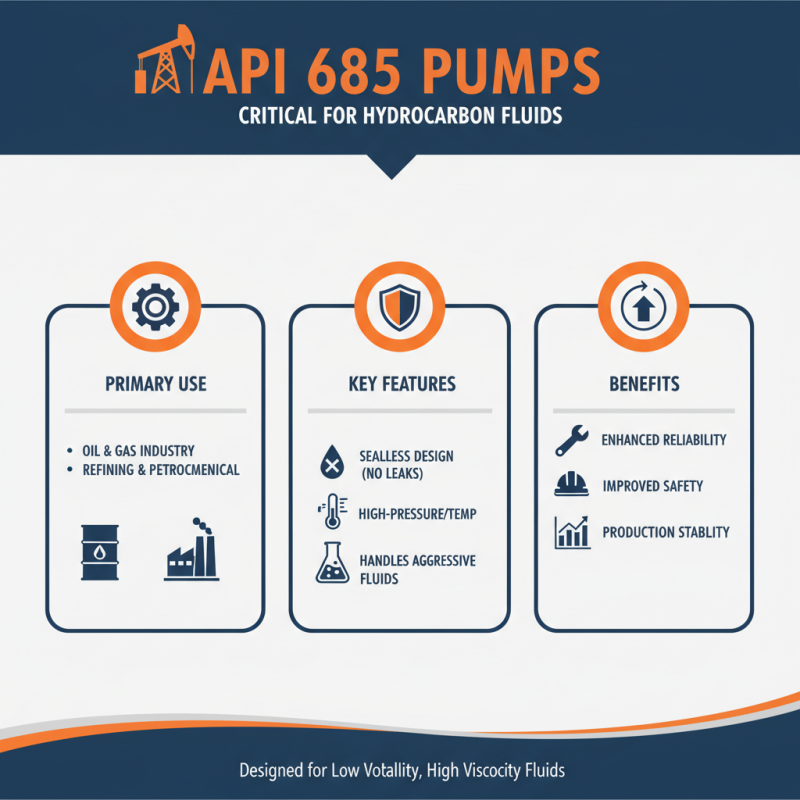

API 685 pumps are designed specifically for handling hydrocarbon fluids in the oil and gas industry, making them crucial for various applications, including refining and petrochemical processes. These pumps are constructed to meet stringent specifications that ensure reliability and safety, particularly in high-pressure and high-temperature environments. Their ability to manage aggressive fluids with low volatility and high viscosity is vital for maintaining stability in production processes, which can otherwise be disrupted by equipment failures or inefficiencies.

When selecting API 685 pumps, it’s essential to consider several factors that contribute to their effectiveness in oil and gas applications. First, ensure that the pump’s materials are compatible with the intended fluids, as this will prevent corrosion and wear over time. Additionally, assess the maintenance requirements of the pump; using pumps that are designed for easy maintenance will minimize downtime and reduce operational costs.

**Tips:** Regular inspections and proper seal systems can significantly enhance the lifespan of API 685 pumps, reducing the risk of leaks and failures. Also, investing in experienced personnel for installation and maintenance can lead to better performance and safety standards in your operations. By prioritizing these aspects, you can ensure that your API 685 pumps operate efficiently and reliably, which is fundamental in the demanding environments of the oil and gas sector.

API 685 pumps have become indispensable in the oil and gas industry due to their unique design features that enhance operational efficiency and safety. One of the primary characteristics of these pumps is their robust mechanical seal arrangement. This feature minimizes the risk of leaks in sensitive applications, ensuring process integrity and protecting the environment. Furthermore, the pumps are designed to handle a wide range of fluids, including corrosive and high-temperature liquids, thus proving their versatility in rugged operational conditions typical in the oil and gas sector.

Another key feature of API 685 pumps is their ability to operate in extreme environments, which is crucial for offshore and remote site applications. The pumps are engineered to withstand high pressures and temperatures while maintaining consistent performance. This reliability reduces downtime and maintenance costs, resulting in enhanced productivity. Additionally, the inherent design promotes efficient fluid dynamics, allowing for optimized flow rates and energy usage, which contribute to the overall economic viability of oil and gas operations. These features collectively underscore the significance of API 685 pumps in ensuring operational excellence and sustainability in the industry.

| Feature | Description | Industry Benefits |

|---|---|---|

| Single Seal Design | Utilizes a single mechanical seal to minimize leakage risks. | Reduces environmental impact and improves safety protocols. |

| Robust Materials | Constructed from high-grade materials like duplex stainless steel. | Enhances durability and extends lifespan leading to cost savings. |

| High Efficiency | Designed for optimal hydraulic performance and low energy consumption. | Improves overall system efficiency, reducing operational costs. |

| Versatile Applications | Suited for a wide range of fluids, including corrosive and viscous liquids. | Flexibility in various applications supports diverse industry needs. |

| Ease of Maintenance | Designed for quick disassembly and easy access to internal parts. | Minimizes downtime during maintenance, enhancing productivity. |

API 685 pumps are specifically designed for high-performance fluid handling in the oil and gas industry, offering significant advantages over conventional pumps. One of their primary benefits is their robust construction, which ensures durability in harsh environments. These pumps are engineered to reduce maintenance needs and extend operational life, which is crucial in industries where downtime can lead to substantial financial losses. The design of API 685 pumps includes features that minimize leakage and emissions, aligning with stringent environmental regulations, making them a responsible choice for modern energy production.

Tips: When selecting a pump for your application, consider the pump materials and seal options to ensure compatibility with the fluids being handled. Investing in pumps that meet API standards can reduce overall operational risks and improve efficiency.

Another advantage of API 685 pumps is their ability to handle a wide range of fluid viscosities and flow rates. This flexibility allows for customization according to specific operational needs, providing an edge over standard pumps that may falter under varied conditions. Additionally, their advanced hydraulic design enhances energy efficiency, leading to reduced operational costs over time. Companies in the oil and gas sector can greatly benefit from evaluating API 685 pumps against other options to find the ideal fit for their unique requirements.

Tips: Regularly assess the performance of pumps in service; this can help identify wear and potential issues early, saving on repair costs and preventing operational disruptions.

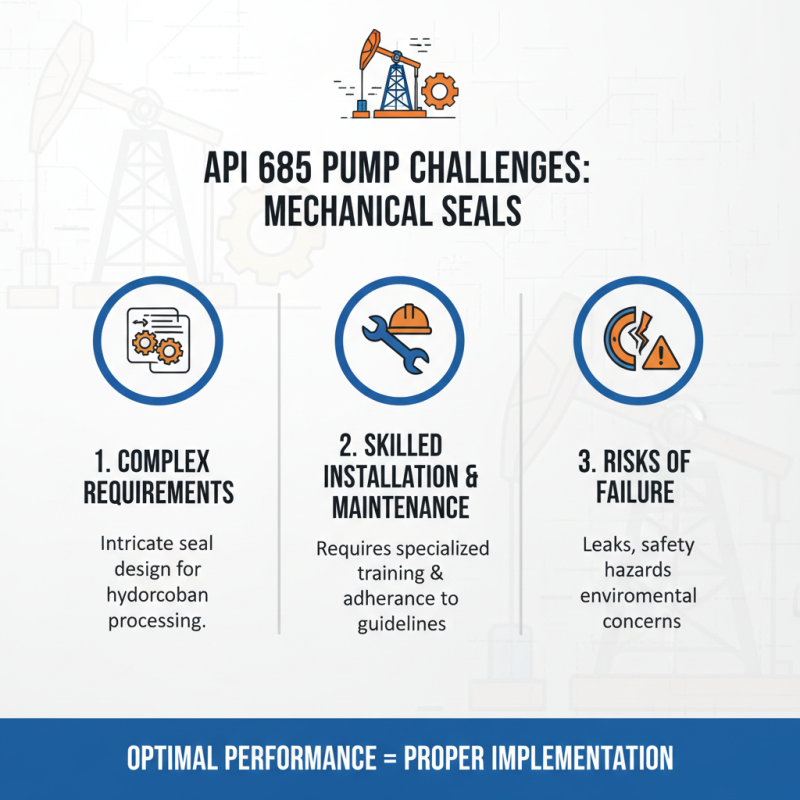

Implementing API 685 pumps in the oil and gas industry presents a range of challenges that must be addressed to ensure optimal performance and safety. One of the primary challenges is the complex requirements for mechanical seals, which are crucial for preventing leaks in hydrocarbon processing. The intricate design necessitates skilled installation and maintenance practices. Without proper training and adherence to guidelines, there's a risk of seal failure, leading to potential safety hazards and environmental concerns.

Another significant challenge is the harsh operating conditions these pumps often face, including high pressures and corrosive environments. Selecting the right materials and ensuring robust construction are vital to withstand these factors. Regular inspections and preventive maintenance strategies are essential to mitigate wear and tear and to maintain peak performance. Additionally, the adaptation of these systems for varying flow rates and fluid characteristics demands a flexible approach, necessitating thorough planning and execution during the design and implementation phases. Addressing these challenges with effective solutions enhances the reliability and efficiency of API 685 pumps, ultimately supporting the sustainability of oil and gas operations.

API 685 pumps are increasingly recognized for their critical role in the oil and gas sector, particularly as the industry evolves to meet new challenges and demands. Recent research indicates that the global market for API 685 pumps is projected to grow significantly, driven by the need for higher efficiency and reliability in fluid transfer applications. According to a report by Grand View Research, the demand for specialized pumps is expected to increase at a CAGR of 4.8% by 2028, emphasizing the importance of API 685 compliance in ensuring process safety and operational efficiency.

Future trends in API 685 pump technology include the integration of smart monitoring systems and advanced materials. The adoption of IoT technologies allows real-time monitoring of pump performance, which can lead to predictive maintenance and reduced downtime. Furthermore, advancements in materials science are facilitating the development of pumps that can handle increasingly aggressive fluids while improving longevity and efficiency. Industry analysts point out that these innovations are essential not only for compliance with environmental regulations but also for optimizing operational costs.

Tips: When selecting an API 685 pump, consider its compatibility with the specific fluids it will handle. Additionally, staying informed about technological advancements in pump monitoring can enhance your operational efficiency. Regularly reviewing maintenance practices and embracing new innovations in pump technology can significantly reduce risks and improve overall system reliability.