Sealless Pumps for a Safer and Greener World

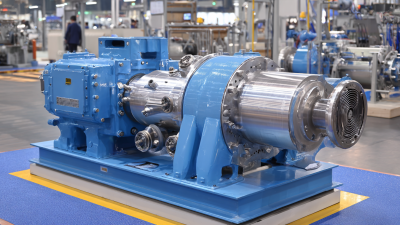

As industries worldwide strive for greater efficiency and sustainable practices, the role of vertical centrifugal pumps has become increasingly critical. These pumps are specifically designed to handle high volumes of fluid with remarkable reliability, showcasing advancements in technology that enhance their operational performance. According to a recent market analysis by Grand View Research, the global centrifugal pump market is projected to reach over $38 billion by 2025, with vertical centrifugal pumps expected to hold a significant share due to their versatility and effectiveness in various applications.

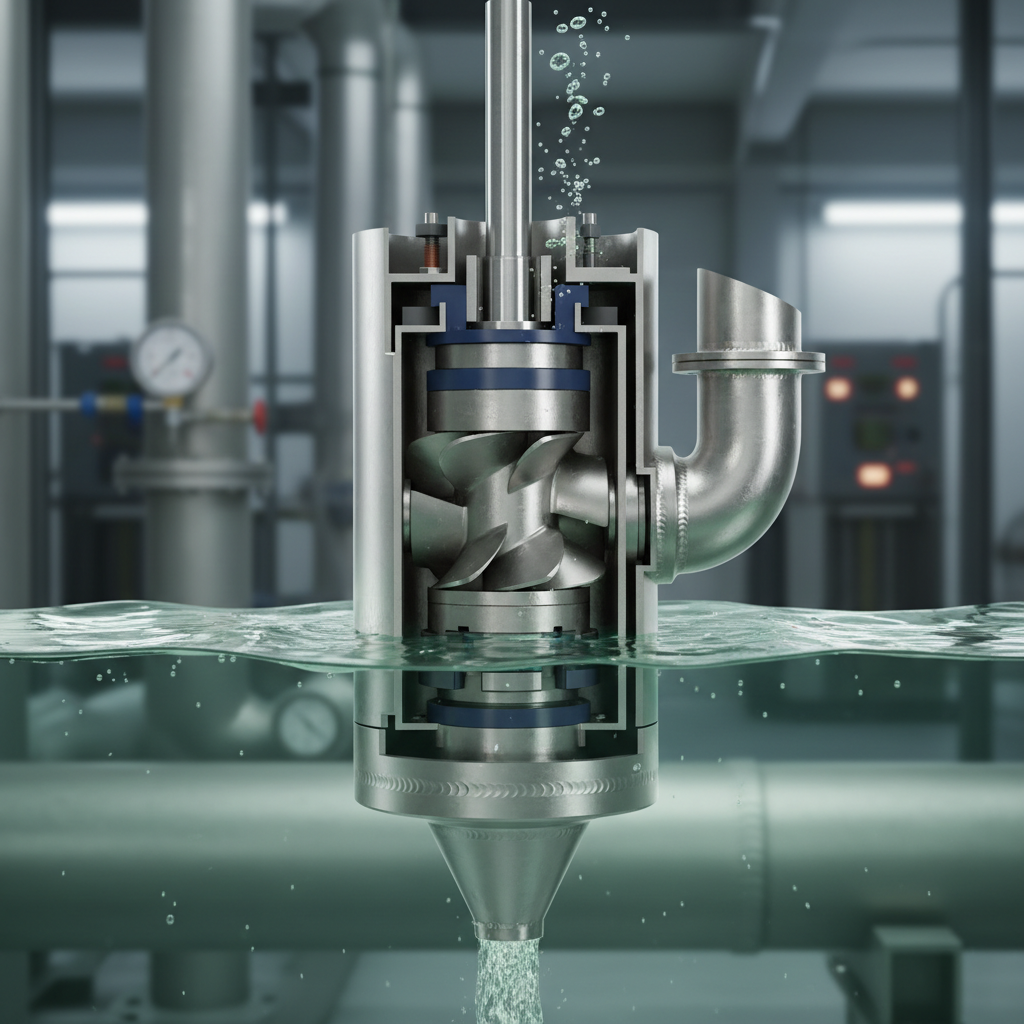

The demand for energy-efficient pumping solutions continues to rise, prompting manufacturers to innovate and improve the design of vertical centrifugal pumps. Innovations such as advanced impeller technology and intelligent control systems have led to pumps that not only consume less energy but also offer higher operational efficiency. A report from the International Energy Agency highlights that optimizing pump efficiency can lead to energy savings of up to 20-30%, emphasizing the importance of adopting cutting-edge solutions in this sector.

In this context, we delve into the top five vertical centrifugal pumps projected for 2025, focusing on their efficiency, innovative features, and the potential impact on industrial operations. As we explore these remarkable advancements, it becomes evident that the future of vertical centrifugal pumps is not just about meeting operational demands but also about contributing to a sustainable and efficient industrial landscape.

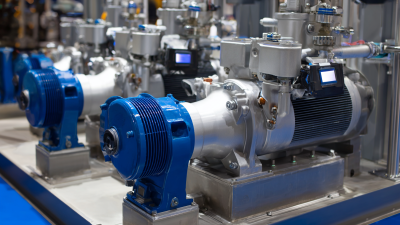

As we approach 2025, the design of vertical centrifugal pumps is evolving to integrate advanced technologies that enhance both efficiency and sustainability. One of the most significant trends is the incorporation of smart sensors and IoT capabilities, allowing for real-time monitoring and predictive maintenance. According to the Global Market Insights report, the vertical centrifugal pump market is expected to register a CAGR of over 6% by 2025, driven largely by these technological advancements. Such innovations facilitate improved operational reliability and reduced downtime, ultimately leading to substantial cost savings for industries reliant on these systems.

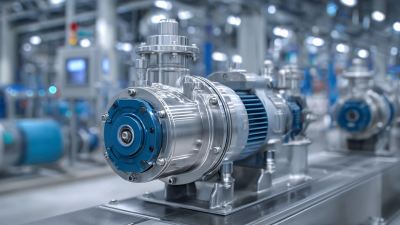

In addition to smart technology, the use of advanced materials is reshaping the landscape of vertical centrifugal pump design. Materials such as corrosion-resistant alloys and high-performance polymers are becoming increasingly prevalent, improving the pumps' longevity and efficiency. The American Society of Mechanical Engineers (ASME) reported that pumps constructed from these innovative materials show a 20% increase in efficiency compared to their traditional counterparts. This shift not only reduces energy consumption but also aligns with global initiatives to adopt greener technologies in industrial applications, thus demonstrating the dual impact of innovation on performance and environmental sustainability.

The realm of vertical centrifugal pumps is evolving rapidly, driven by groundbreaking innovations that enhance efficiency and performance. Manufacturers are increasingly integrating smart technology into their designs, allowing for real-time monitoring and adjustments. These advancements not only improve operational efficiency but also reduce energy consumption, ultimately lowering operational costs for industries that rely on these pumps.

One key innovation is the incorporation of variable frequency drives (VFDs), which enable pumps to adjust their speed according to demand. This flexibility helps to maintain optimal operating conditions and minimizes wear and tear on the equipment. Additionally, advanced materials are being used to increase resistance to corrosion and abrasion, extending the lifespan of the pumps and improving reliability.

Tips: When selecting a vertical centrifugal pump, consider the specific requirements of your application. Assess flow rates, head pressures, and the characteristics of the fluid being pumped. Opt for models with built-in predictive maintenance features to enhance pump longevity and performance. Additionally, always consult with pump specialists to ensure you choose the right technology tailored to your needs, as this can significantly impact overall efficiency.

The centrifugal pump market is on the rise, with a valuation projected to reach $44.90 billion in 2025. This growth is driven by the increasing demand for efficient and innovative pumping solutions across various industries, including mining, water treatment, and chemical processing. Comparative analyses of leading vertical centrifugal pumps are essential for stakeholders to understand performance metrics, energy efficiency, and innovative features being introduced into the market.

Recent studies highlight the hydrodynamic performance of various centrifugal designs, focusing particularly on their operational efficiencies under different speed modulations. As industry players strive for modernization, advancements in centrifugal pump technologies, such as the integration of brushless DC motors and switched reluctance motors, promise substantial improvements in energy consumption and reliability. The ongoing exploration and comparison of these innovations will be critical in establishing the top contenders in the vertical centrifugal pump market for 2025.

The materials used in the construction of vertical centrifugal pumps play a crucial role in their overall performance and efficiency.

Different materials can significantly affect the pump’s resistance to corrosion, wear, and temperature fluctuations. For instance, pumps made from

stainless steel or high-grade alloys are commonly chosen for their durability and ability to handle aggressive fluids, making them ideal for industrial applications.

The right material can enhance the lifespan of the pump, thereby reducing maintenance costs and downtime.

Moreover, advancements in material science have led to the introduction of composite materials and coatings that not only improve strength but also optimize the hydrodynamic characteristics of pump components.

These innovations facilitate higher efficiency levels and can even reduce energy consumption during operation. As industries increasingly seek solutions to minimize their carbon footprint,

selecting pumps constructed from innovative materials becomes a key factor in achieving energy-efficient systems. Understanding the impact of these materials is vital for making informed decisions about pump design and application

in 2025 and beyond.

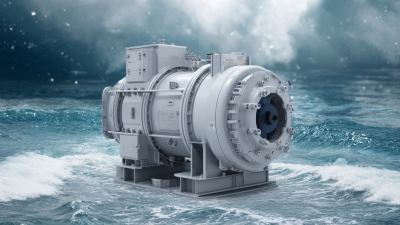

The advancement of vertical centrifugal pump technology brings both opportunities and challenges as industries strive to implement sustainable practices. Breakthrough innovations in solar, wind, hydrogen, and energy storage are reshaping the landscape for these pumps, enhancing efficiency and reducing environmental impact. By adopting renewable energy sources, vertical pump technology can significantly lower operational costs while maintaining effective performance. This transition also opens doors for collaborations across different sectors, fostering an ecosystem where renewable technologies can thrive.

However, the journey toward innovation is not without hurdles. The oil and gas industry, for instance, faces a myriad of challenges including changing policies, rising operational expenses, and the urgency for digital transformation. Navigating these complexities while pursuing growth in areas like LNG requires a strategic approach. Companies must embrace new digital tools and adapt to evolving market demands to ensure long-term resilience. In this dynamic environment, the integration of new technologies within fire protection and other critical applications will play a pivotal role in addressing both current and future industry demands.