Sealless Pumps for a Safer and Greener World

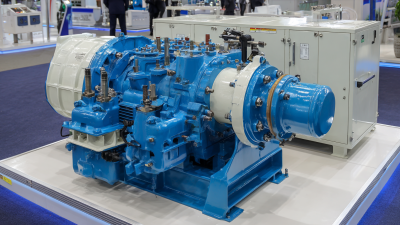

In today's industrial landscape, efficiency and reliability are paramount, especially when it comes to fluid transfer systems. Among the various pump technologies available, the canned motor pump has emerged as a preferred solution due to its unique design and operational advantages. By sealing the motor within a can-like enclosure, this type of pump eliminates the need for traditional shaft seals, significantly reducing the risk of leaks and enhancing the safety of fluid handling processes.

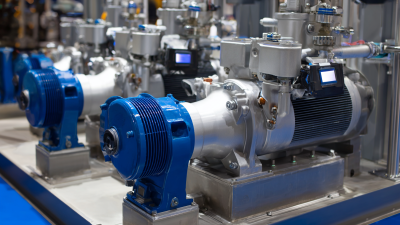

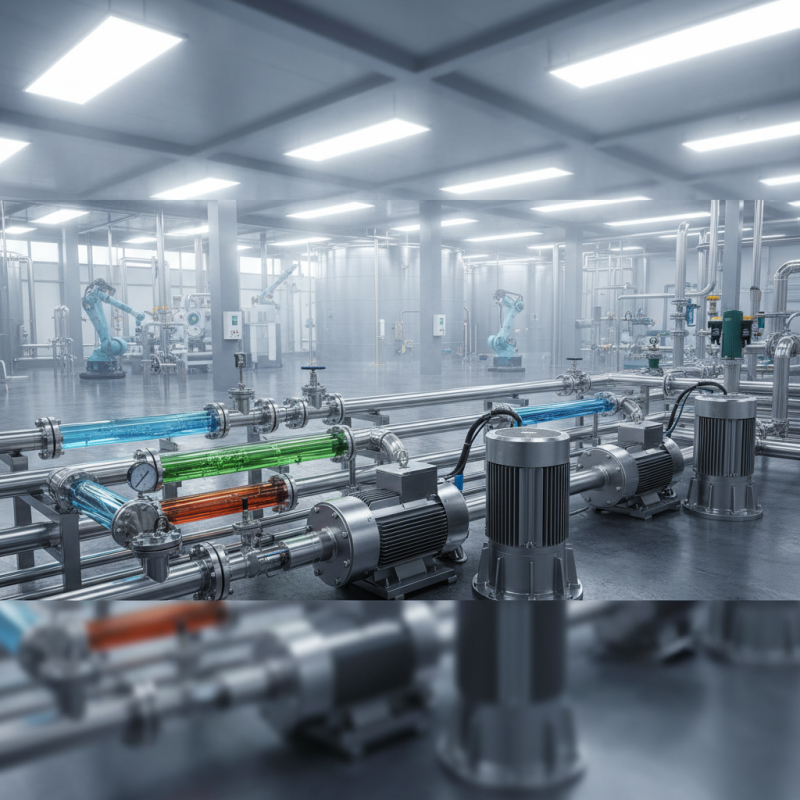

As we look ahead to 2025, understanding the key features, benefits, and applications of canned motor pumps will be crucial for industries aiming to optimize their operations. These pumps are not only known for their durability and low maintenance requirements but also for their ability to handle a wide range of corrosive and hazardous fluids. This versatility makes them ideal for sectors such as chemical processing, water treatment, and HVAC, where reliable performance is essential.

In this article, we will delve into the top features of canned motor pumps, highlighting their benefits and exploring the various applications that are revolutionizing the way fluids are managed across multiple industries. Whether you are an industry professional or simply looking to enhance your knowledge, this comprehensive overview will provide valuable insights into why canned motor pumps are becoming increasingly indispensable.

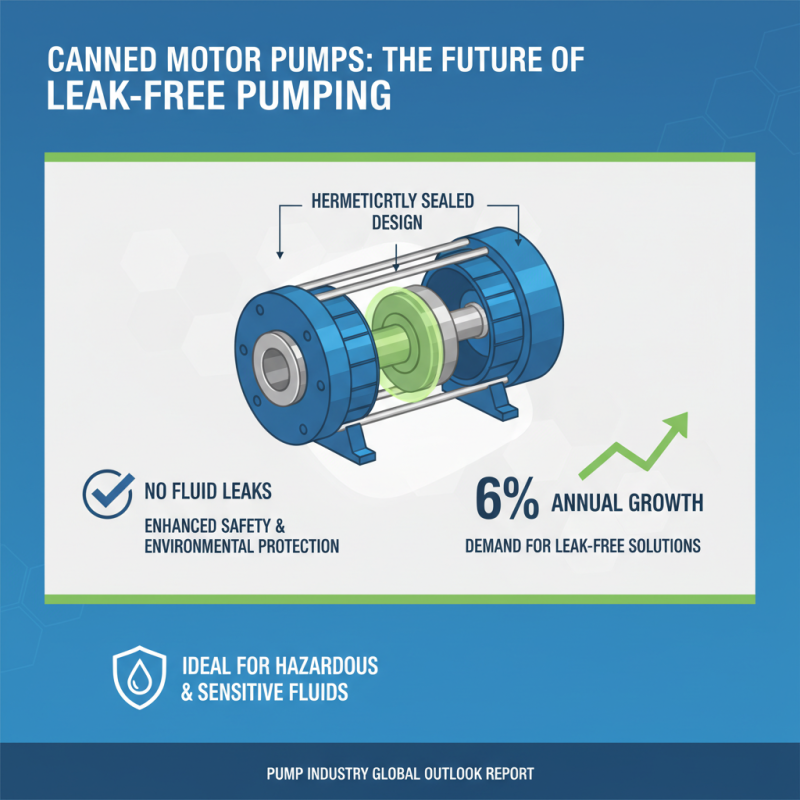

Canned motor pumps are becoming increasingly popular in various industries due to their distinct features and benefits. One of the key advantages of these pumps is their hermetic design, which allows for the safe transport of fluids while eliminating the risk of leaks. According to a 2022 market analysis by Research and Markets, the global canned motor pump market is projected to grow at a compound annual growth rate (CAGR) of 6.5% from 2023 to 2030, reflecting an increasing reliance on these efficient systems in sectors such as chemical processing, water supply, and HVAC applications.

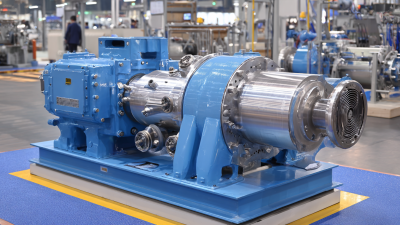

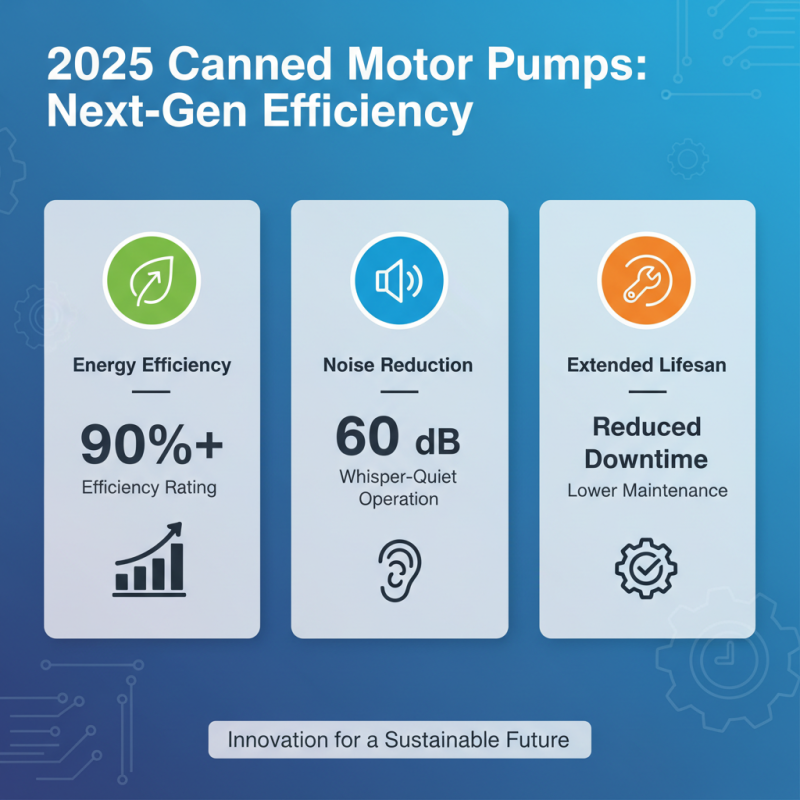

In terms of functionality, 2025 canned motor pumps are expected to include enhanced energy efficiency and compact designs, reducing the overall footprint while maximizing performance. Industry reports indicate that these pumps can achieve up to 90% efficiency, meaning lower operational costs and reduced environmental impact. The integration of smart technology, such as IoT capabilities for real-time monitoring and predictive maintenance, is also anticipated to become a standard feature, addressing the growing demand for automation in industrial environments. As industries continue to prioritize sustainability and efficiency, the demand for these innovative pumping solutions is set to rise significantly.

Canned motor pumps are increasingly recognized for their unique advantages in various industrial applications. One of the primary benefits is their hermetically sealed design, which eliminates the risk of leaking fluids, ensuring safety and environmental protection. According to a recent report from the Pump Industry Global Outlook, the demand for leak-free pumping solutions is projected to grow by 6% annually, driven by increased regulatory pressures on industries to minimize spills and emissions. This safety feature makes canned motor pumps particularly suitable for handling hazardous or sensitive fluids, where containment is critical.

In addition, these pumps operate quietly and have low vibration levels, making them ideal for use in environments where noise reduction is a concern. The Energy Institute's analysis shows that the operational efficiency of canned motor pumps can lead to energy savings of up to 30% compared to traditional pump systems. This not only reduces operational costs but also contributes to sustainability goals by lowering power consumption and the carbon footprint of industrial processes.

Tips: When selecting a canned motor pump for your application, consider the specific fluid properties and operational requirements to ensure optimal performance. Additionally, regular maintenance checks can extend the lifespan of the pump and enhance its operational efficiency. It is also advisable to stay informed about the latest advancements in pump technologies to make the best investment decisions for your industrial needs.

Canned motor pumps have gained significant traction across various industries due to their unique design and operational benefits. These pumps, which feature a motor encased in a protective structure, eliminate the risk of leakage and enhance operational safety. Industries such as chemical processing, oil and gas, and water management are increasingly adopting canned motor pumps to minimize environmental risks and ensure efficient fluid handling. The ability to operate in challenging environments, coupled with reduced maintenance needs, makes these pumps particularly appealing for applications requiring reliability.

Recent trends in the development of canned motor pumps focus on improving energy efficiency and integrating smart technology. Innovations such as advanced monitoring systems allow for real-time performance tracking, reducing downtime and enabling predictive maintenance. Moreover, the increasing emphasis on sustainability has propelled the design of these pumps to accommodate eco-friendly fluids and reduce energy consumption. As industries continue to prioritize safety and efficiency, canned motor pumps are poised to play a vital role in various applications, further solidifying their importance in modern industrial processes.

The 2025 models of canned motor pumps have been designed with cutting-edge technology to enhance operational efficiency across various applications. Key technical specifications include increased energy efficiency ratings, often surpassing 90%, which aligns with global sustainability goals. Many models now feature noise reduction technologies, achieving noise levels as low as 60 dB, making them suitable for installation in noise-sensitive environments. Moreover, improvements in seal technology have significantly extended the mean time between failures (MTBF), contributing to lower maintenance costs and minimizing downtime.

Performance data highlights that these advanced canned motor pumps offer flow rates ranging from 10 to 1,000 GPM, meeting diverse industrial needs. They can operate in temperatures up to 300°F, utilizing materials that resist corrosion and wear, thereby enhancing longevity. Recent industry reports indicate that the adoption of canned motor pumps is on the rise, with a projected growth rate of 7% annually through 2025, driven by their reliability and reduced environmental impact. This makes them a preferred choice in sectors like HVAC, petrochemical, and food processing, where both performance and sustainability are essential.

The canned motor pump market is poised for significant growth in the coming years, driven by the increasing demand across various industrial applications. As industries continue to focus on efficiency and sustainability, the appeal of canned motor pumps—known for their compact design and minimized environmental impact—will likely intensify. With their enclosed structure, these pumps offer improved safety and reduced maintenance needs, positioning them as an attractive option for sectors such as chemicals, pharmaceuticals, and food processing.

Future projections indicate a robust expansion in specific markets due to technological advancements and rising safety regulations. The demand for energy-efficient solutions is escalating, leading to more manufacturers investing in research and development to enhance the performance and longevity of canned motor pumps. Additionally, the growing trend of automation in manufacturing processes will further augment the adoption of these pumps. As industries evolve, the focus on reliability and low operational costs will compel stakeholders to turn to innovative pumping solutions, ensuring that canned motor pumps remain a crucial part of their supply chains.